A Globe Valve is a type of linear motion valve used to control the flow of fluids or gases within a pipeline. It features a disk or plug that moves perpendicular to the flow, allowing for precise regulation of flow rate.

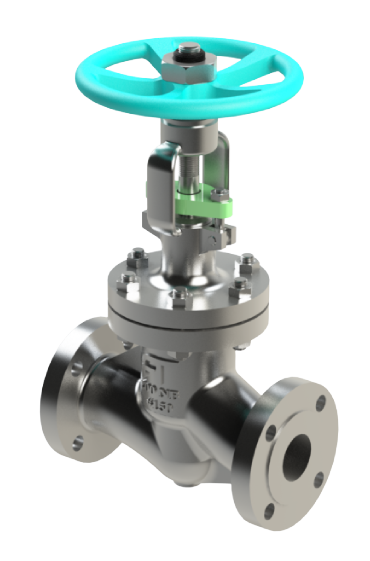

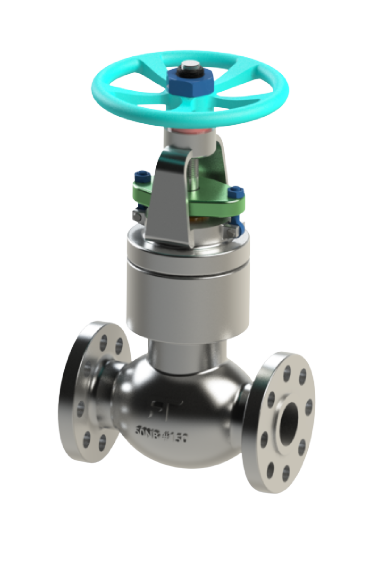

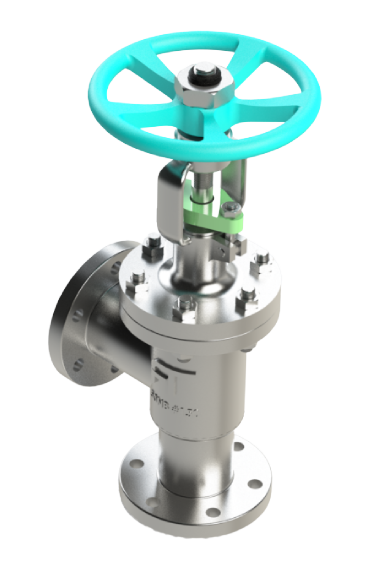

Forged Globe Valve

Forged globe valves are made from high-quality components and are strictly inspected by skilled quality controllers.

We are the leading Forged Globe Valve manufacturer in Mumbai, India. A forged globe valve is an industrial valve used for controlling fluid flow in pipelines and systems. It is typically made through a forging process, ensuring strength and durability. The valve consists of a body, bonnet, disc, stem, and valve seat. By raising or lowering the disc with the stem, the valve regulates fluid flow accurately. Forged globe valves are known for their robust construction, making them suitable for high-pressure and high-temperature applications. They find use in industries like oil and gas, petrochemicals, and power generation, where precise flow control is crucial, and they excel in preventing leakage when closed.

The Working Mechanism of Forged Globe Valve

Forged Globe Valves are engineered to regulate the flow of fluids, making them an essential component in various industries such as petrochemicals, oil and gas, power generation, and more. The unique design of the Forged Globe Valve allows for precise control of flow rates, making it ideal for applications where accuracy is paramount.

The key working components of Freture Techno's Forged Globe Valve include:

1. Body: The robust forged body ensures durability and can withstand high-pressure environments.

2. Bonnet: The bonnet houses the valve's stem and packing, providing a seal to prevent leakage.

3. Disc (Plug): This component is responsible for controlling the flow by moving up or down within the valve seat.

4. Stem: The stem connects the handwheel or actuator to the disc, allowing for manual or automated control.

5. Valve Seat: The valve seat is where the disc forms a tight seal, controlling the flow of fluid.

Key Features of Forged Globe Valve

Freture Techno's Forged Globe Valve stands out due to its exceptional features:

1. Robust Construction: Crafted from high-quality forged materials, these valves are built to withstand extreme temperatures and pressures, ensuring longevity and reliability.

2. Precise Flow Control: The design of the globe valve allows for fine-tuned control of flow rates, making it suitable for applications where accuracy is crucial.

3. Leak Prevention: Freture Techno's Forged Globe Valve is designed to provide a tight and secure seal, effectively preventing leakage, which is vital in industries dealing with hazardous fluids.

4. Versatility: These valves are suitable for various media, including gases, liquids, and steam, making them highly versatile in multiple industries.

5. Easy Maintenance: The straightforward design and accessibility of components make maintenance and repairs hassle-free, minimizing downtime.

Applications of Forged Globe Valve

Freture Techno's Forged Globe Valve finds its application across a broad spectrum of industries, including:

1. Oil and Gas: Used in upstream and downstream operations to regulate the flow of crude oil, natural gas, and refined products.

2. Petrochemical: Ideal for controlling the flow of chemicals and solvents in the production process.

3. Power Generation: Essential for controlling steam flow in power plants and ensuring efficient energy production.

4. Water Treatment: Used in water distribution systems and wastewater treatment plants for precise flow control.

5. Industrial Manufacturing: Employed in various manufacturing processes requiring accurate fluid control.

Why Choose Freture Techno for Forged Globe Valves?

There are compelling reasons why Freture Techno is the preferred choice for Forged Globe Valves:

1. Exceptional Quality: Freture Techno is renowned for its commitment to quality, ensuring that each valve meets rigorous industry standards.

2. Customization: Freture Techno offers tailored solutions to meet specific application requirements, ensuring that you get the perfect valve for your needs.

3. Expertise and Support: With years of experience in valve manufacturing, Freture Techno provides expert guidance and support to help you select the right valve for your application.

4. Competitive Pricing: Freture Techno offers competitive pricing without compromising on quality, making it a cost-effective choice.

5. Quick Delivery: With a well-established distribution network, Freture Techno ensures timely delivery, reducing downtime for your operations.

When it comes to precision flow control, durability, and reliability, Freture Techno's Forged Globe Valve stands head and shoulders above the competition. With a commitment to quality, customization options, expert support, competitive pricing, and quick delivery, Freture Techno is your trusted partner for all your globe valve needs. Upgrade your fluid control systems with Freture Techno's Forged Globe Valve and experience the difference in performance and reliability.

Specifications |

Features |

|---|---|

|

End Connection: Screwed (ANSI 1.20.1) / Socket Weld (B-16.11) Size: 15 NB - 50 NB Pressure Rating: #800 - #2500 Temperature Range: -190° C to 350 ° C MOC: Carbon Steel / Stainless Steel / Alloy Design Standard: API 602 Operation: Handwheel / Actuated Fire safe design: API 6FA Testing: API 598 Rev 2009 / ISO 15848 Documents: BS/EN 10204-3.1 REV 2019 |

|

Related Products

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

-

What is a Globe Valve?

-

How does a Globe Valve work?

Globe valves operate by raising or lowering the disk or plug within the valve body. When the valve is fully open, the disk is lifted, permitting maximum flow. Closing the valve lowers the disk, restricting flow.

-

Where are globe valves commonly used?

Globe valves are found in various industries, including oil and gas, power generation, water treatment, HVAC systems, and more. They are often used in applications that require throttling, precise flow control, or isolation.

-

Are Globe Valves safe and easy to use?

Globe Valves, given their special ability to function flawlessly at extremely high temperatures, are one of the safest valves to use.

At Freture, all our valves are manufactured as per international standards. Are 100% leak-proof and emission free. Saves down-time and process media. Maintenance free. Easy to install and remove.

-

Do I really need a Globe Valve for my factory?

If you are in one of the following industries, a Globe Valve will definitely help you improve the efficiency and safety.

- Chemical Manufacturing

- Oil & Gas Refineries

- Boiler / Reactor Manufacturing

- EPC Contractor company

- Local Traders

If you’re from another industry looking for more details about how you can benefit from using a Globe Valve, please get in touch with us here for further discussion.

-

What are the advantages of using Globe valves?

Globe valves offer excellent flow control, minimal pressure drop, and the ability to handle high-pressure and high-temperature fluids. They provide a reliable shutoff and can be used for both on-off and throttling services.

-

Can Globe Valves be used for both upward and downward flow?

Yes, Globe Valves can be used for both upward and downward flow. The flow direction is indicated by the arrow on the valve body, ensuring proper installation.

-

Can Globe Valves be Automated?

Yes, Globe Valves can be automated using various types of actuators, such as electric, pneumatic, or hydraulic. Automation enables remote operation, integration into control systems, and precise flow regulation.

-

Why is Freture the best place to buy Globe Valves from?

Most of the time our clients are local hence we are easily accessible

Our products are manufactured & Tested as per international Std. & we offered only best quality product

We will keep stock of Std. Product for last minute urgency

We provide products only from reputed & highly reliable manufactured

We have an experienced technical team who will be able to understand client’s exact requirements & accordingly we will offer solutions

-

What is the difference between a Globe Valve and a Gate Valve?

While both are linear motion valves, the key difference is in the mechanism and flow control. A Globe valve controls flow by raising or lowering a disk perpendicular to the flow, allowing precise regulation. A Gate valve controls flow with a flat or wedge-shaped gate that moves parallel to the flow.

-

How do I know which type of Globe Valve is ideal for me?

Get in touch with us here and an expert from Freture Techno will help you decide.

Industries where Globe Valve is Used

Chemical Manufacturing

Oil & Gas Refineries

Boiler / Reactor Manufacturing

EPC Contractor company

Local Traders

Applications of Globe Valve

- Used in places where leakage is a concern.

- Feed-water, chemical, air, lube oil.

- Ideal for places where the machine operates at a constant pressure.