A Ball Valve is a type of quarter-turn valve that uses a hollow, perforated, and pivoting ball to control the flow of liquids or gases through it.

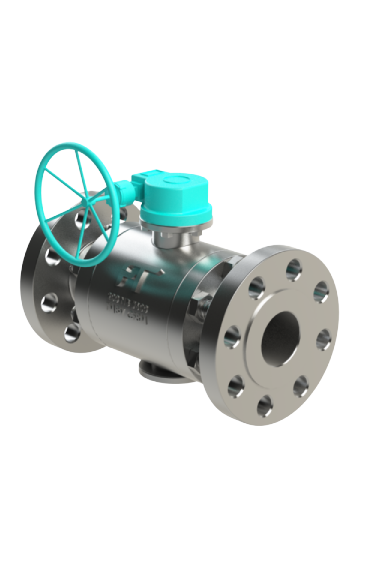

Ball Valves

A Ball Valve is extremely safe and reliable.

Freture is a leading Ball Valve manufacturers in Mumbai, India. Ball valves are a type of quarter-turn valve that uses a hollow, perforated, and pivoting ball to isolate and control Flow through it.

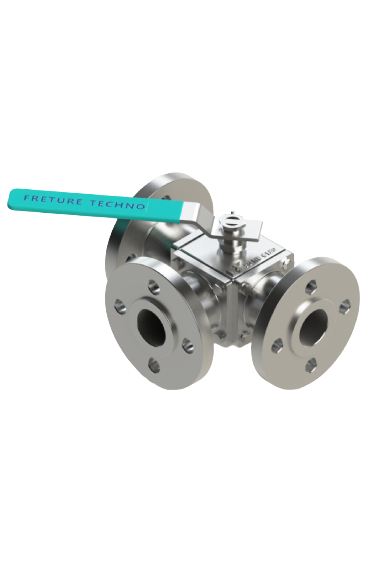

Freture Ball valves are made with high-quality materials and are designed as per API / ASME / ISO / BS standards to withstand high pressures, temperatures, and corrosive applications. We offer a complete range of quarter turn ball valves with different specifications, such as full bore or reduced bore, Flanged Threaded - Butt Weld - Socket Weld, and various Seats Materials (Soft Seated & Metal Seated) to suit process requirements.

Ball Valves are Manual & Automated devices used in Process Piping, a utility to control & isolate the flow of fluids or gases through a pipe. They consist of a hollow ball or sphere with a hole in the middle, which is rotated using a lever or Actuator to control / Isolate the fluid flow.

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is a Ball Valve?

- How does it work?

A Ball Valve operates by rotating a spherical disc (the ball) inside the valve body. When the handle is turned perpendicular to the pipe, the valve is closed, and when it's parallel, the valve is open, allowing fluid to flow through.

- What are the main applications?

Ball Valves are widely used in various industries such as oil and gas, chemical processing, water and wastewater treatment, HVAC systems, and residential plumbing. They are suitable for applications requiring efficient shut-off and control of flow.

- What are the benefits of using one?

Benefits include reliable sealing, quick operation, minimal pressure drop, excellent flow control, durability, and suitability for a wide range of temperatures and pressures.

- What materials are used in their construction?

Ball Valves can be made from a variety of materials including stainless steel, brass, bronze, cast iron, and various plastics such as PVC, CPVC, and PTFE, with the choice depending on the application's requirements.

- How do I choose the right one for my application?

Consider factors such as the type of fluid, pressure and temperature conditions, flow rate, pipe size, end connections, and the specific requirements of your system to select the appropriate Ball Valve.

- Can they be repaired?

Yes, Ball Valves can be repaired, typically by replacing the worn or damaged components such as the seals, seats, or ball. However, this depends on the extent of damage and the valve's design.

- What maintenance is required?

Regular inspection and lubrication of moving parts are essential for maintaining optimal performance. Additionally, periodic testing for leaks and checking for any signs of wear or corrosion is recommended.

- Are they available in different designs?

Yes, Ball Valves come in various designs including two-way, three-way, and multi-port configurations, as well as different end connections such as threaded, flanged, and welded.

- Why is Freture the best place to buy Ball Valves from?

Freture offers high-quality Ball Valves made from superior materials, a wide selection of designs to meet diverse needs, expert support for optimal valve selection, competitive pricing, and excellent after-sales support and warranty services.

Industries where Ball Valve is Used

Oil and Gas Industry

Chemical Processing

Wastewater Management

HVAC

Petrochemical Industry

Applications of Ball Valve:

- Isolation: They are commonly used for on/off control and isolation of fluid flow in pipelines.

- Flow Control: They are ideal for precise flow control due to their quarter-turn operation, making them suitable for throttling applications.

- High Pressure and Temperature: They are suitable for high-pressure and high-temperature applications, including in oil and gas pipelines and steam systems.

- Versatile Usage: Widely employed in various industries such as oil and gas, chemical processing, water treatment, and HVAC.

- Quick Operation: They offer quick and reliable operation, making them suitable for emergency shut-off and critical processes.