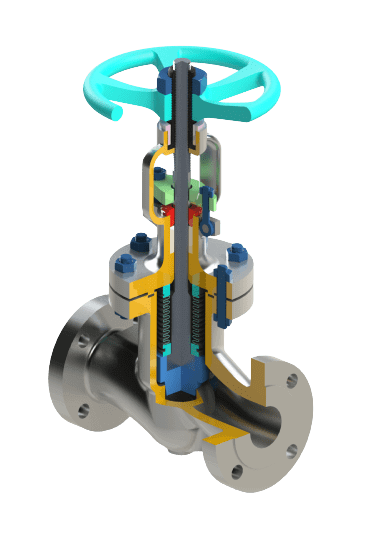

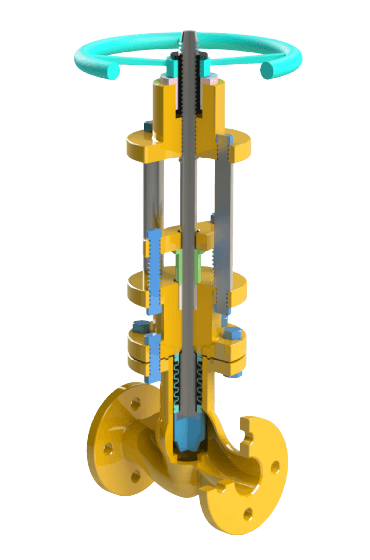

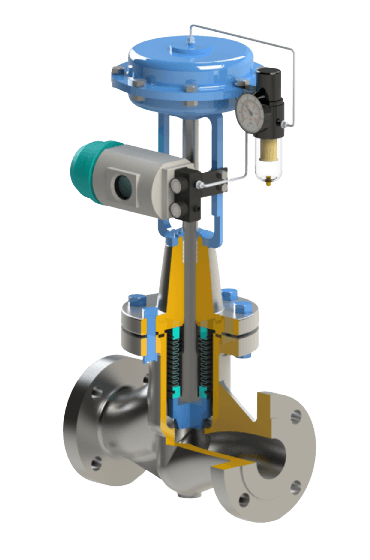

A Bellow Seal Globe Control Valve is a type of valve that uses a metallic bellows to create a hermetic seal, preventing fluid leakage. This design is particularly effective in applications requiring high levels of sealing performance, such as in handling hazardous or toxic media.

Bellow Seal Globe Control Valve

A Bellow Seal Control Globe Valve is a construction that is a kind of Globe control valve that seals the valve stem components using bellow.

Freture Techno is the leading Bellow Seal Control Valves Manufacturer in Mumbai, India. When it comes to precise fluid control, the Bellow Seal Control Globe Valve stands as a paragon of engineering excellence. As a leading Bellow Seal Control Globe Valve manufacturer, Freture Techno takes pride in offering a comprehensive range of these valves that consistently deliver top-notch performance in diverse industrial applications.

Bellow Seal Globe Control Valve: Engineering Excellence Unveiled

Our Bellow Seal Globe Control Valves are meticulously designed and engineered to provide impeccable control over fluid flow. Here's why they are the preferred choice for demanding applications:

- Leak-Free Performance: The bellows seal design ensures a hermetic seal, preventing any fugitive emissions and making these valves ideal for hazardous or environmentally sensitive processes.

- Precise Flow Control: With their robust construction and advanced design, our Bellow Seal Globe Control Valves offer accurate and repeatable control over flow rates, enabling optimal process performance.

- Corrosion Resistance: Crafted from high-quality materials, these valves are corrosion-resistant, ensuring longevity and reliability in aggressive chemical environments.

- Minimal Maintenance: Their design minimizes wear and tear, reducing downtime and maintenance costs, while also extending the valve's service life.

- Wide Range of Applications: Bellow Seal Control Valves find their application across various industries, including chemical processing, pharmaceuticals, petrochemicals, and more, thanks to their versatile design.

Why Choose Freture Techno for Bellow Seal Control Globe Valves?

When you opt for Freture Techno, you unlock:

- Engineering Expertise: Benefit from our extensive knowledge and experience in manufacturing precision-engineered Bellow Seal Control Valves.

- Quality Assurance: Our valves adhere to stringent quality standards and undergo rigorous testing, ensuring you receive reliable and consistent performance.

- Custom Solutions: We offer tailored solutions to match your specific application requirements, from valve size and end connections to material selection.

- Global Reach: As a worldwide supplier, we serve clients not only as a Bellow Seal Control Valve manufacturer but also as a trusted partner committed to your success.

- Dedicated Support: Our customer support team is ready to assist you at every step, from valve selection to post-installation service.

Elevate your fluid control systems with Freture Techno's Bellow Seal Globe Control Valves. Contact us today to discover how our precision-engineered valves can enhance your processes and ensure utmost reliability in fluid control.

Specifications | Features |

|---|---|

Type : Globe Control Valve End Connection: Flange (B16.5) / Butt Weld (B16.25) Size: 15 NB - 600 NB Pressure Rating: #150 - #900 Temperature Range: -190° C to 350 ° C MOC: Carbon Steel / Stainless Steel / Alloy Design Standard: MSS SP-117 / API 623 Cycle Life: 3000 - 5000 - 10000 Cycle Face to Face: ASME B16.10 Rev 2009 Operation: Manual & Actuated (Diaphragm / Electric / Gear / Cylindrical) Fire safe design: API 6FA Testing: API 598 Rev 2009 / ISO 15848 Documents: BS/EN 10204-3.1 REV 2019 |

|

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is a Bellow Seal Globe Control Valve?

- How does it work?

A Bellow Seal Globe Control Valve operates by using a flexible bellows element to seal the valve stem, preventing any fluid from leaking out along the stem. When the valve is actuated, the bellows flexes but maintains a tight seal, allowing precise control of fluid flow while ensuring leak-free operation.

- What are the main applications?

Bellow Seal Globe Control Valves are commonly used in industries such as chemical processing, pharmaceuticals, oil and gas, and power generation. They are ideal for applications involving toxic, hazardous, or high-purity fluids where preventing leakage is critical.

- What are the benefits of using one?

The primary benefits of using a Bellow Seal Globe Control Valve include superior sealing capabilities, reduced risk of leakage, enhanced safety, and long-term reliability. These valves also minimize maintenance requirements and downtime, making them cost-effective over their lifecycle.

- What materials are used in their construction?

Bellow Seal Globe Control Valves are typically constructed from materials such as Carbon Steel, Stainless Steel, and various Alloys. The choice of material depends on the specific requirements of the application, including temperature, pressure, and the nature of the fluid being handled.

- How do I choose the right one for my application?

Selecting the appropriate Bellow Seal Globe Control Valve involves considering factors such as the type of fluid, operating pressure and temperature, required flow rate, and specific industry standards. Consulting with a valve specialist can help ensure the correct valve is chosen for your specific needs.

- Can they be repaired?

Yes, Bellow Seal Control Globe Valves can be repaired. It is essential to follow the manufacturer's guidelines and use authorized service providers to ensure proper repair and maintain the valve's integrity and performance.

- What maintenance is required?

Maintenance for Bellow Seal Control Globe Valves typically includes regular inspections, cleaning, and testing to ensure they are functioning correctly. Periodic replacement of worn components, such as the bellows, may also be necessary to maintain optimal performance.

- Are they available in different designs?

Yes, Bellow Seal Globe Control Valves are available in various designs to suit different applications. These designs can include different end connections (such as flanged or butt-weld), pressure ratings, sizes, and materials, allowing customization to specific requirements.

- What standards govern the manufacturing of Bellow Seal Control Globe Valves?

The manufacturing of Bellow Seal Control Globe Valves is governed by standards such as MSS SP-117, API 623, ASME B16.10 Rev 2009, API 6FA, and API 598 Rev 2009. These standards ensure the valves meet rigorous performance, safety, and quality requirements

Industries Where Bellow Seal Globe Control Valve is used

Oil and Gas Industry

Petrochemical Industry

Chemical Processing Industry

Power Generation Industry

Pharmaceutical Industry

Applications of Bellow Seal Globe Control Valve

- Chemical Processing: Handling corrosive, toxic, and hazardous chemicals.

- Oil Refining: Controlling the flow of crude oil, refined products, and petrochemicals.

- Power Generation: Regulating steam and water flow in power plants.

- Pharmaceutical Production: Maintaining contamination-free processes for high-purity fluid handling.

- HVAC Systems: Controlling the flow of water, steam, and other fluids in heating, ventilation, and air conditioning systems.