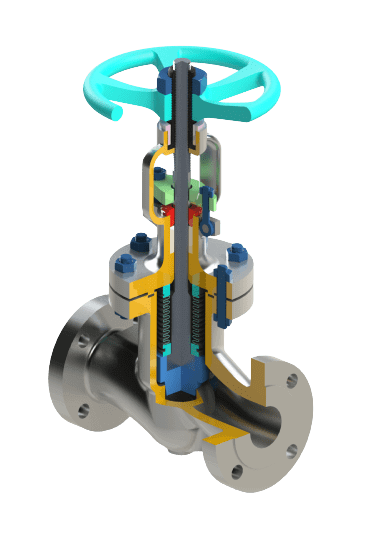

A Bellow Seal Globe Euro-Chlor Valve is a type of valve designed with a bellows seal to prevent leakage and ensure a tight seal in various industrial applications.

Bellow Seal Globe Euro-Chlor Valve

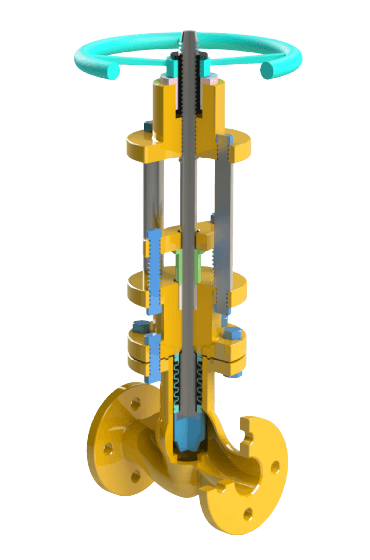

Euro-Chlor Bellow Seal Globe Valve- featuring ASME B 16.5 flanges, ASME B 16.10 face-to-face flanges, ACME screw thread stem, and grounded shaft.

Multiple wall liquid-protected bellow built of Hastelloy C 276 with a minimum life cycle of 10,000 cycles, metal back seat, PTFE safety stuffing box packing, stainless steel spiral wound bonnet gasket with PTFE filler material and housed in a tongue and grooved flange. The Globe valve was tested in accordance with EURO CHLOR GEST 89/140.

Specifications | Features |

|---|---|

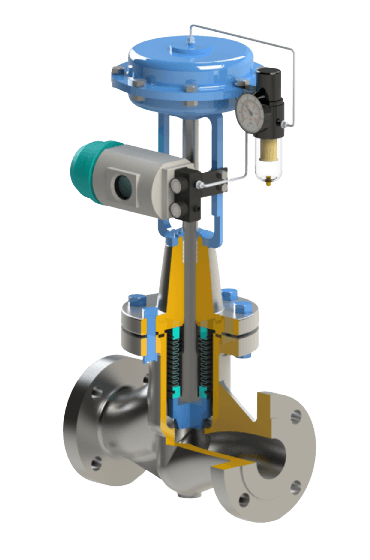

Type: Globe End Connection: Flange (B16.5) Size: 15 NB - 600 NB Class: #150 - #300 Temperature Range: -190° C to 350 ° C MOC: LOW Temp. Carbon Steel / Stainless Steel / Alloy Design Standard: EURO CHLOR GEST 89-140 / API 623 Cycle Life: 3000 - 5000 - 10000 Cycle Face to Face: ASME B16.10 Rev 2009 Operation: Manual & Actuated (Diaphragm / Electric / Gear / Cylindrical) Fire safe design: API 6FA Testing: EURO CHLOR GEST 89-140 / API 598 Rev 2009 / ISO 15848 Documents: BS/EN 10204-3.1 REV 2019 |

|

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is a Bellow Seal Globe Euro-Chlor Valve?

- How does it work?

A Bellow Seal Globe Euro-Chlor Valve operates by using a bellows seal mechanism, which provides a flexible barrier to prevent fluid leakage while allowing smooth operation of the valve stem.

- What are the main applications?

Bellow Seal Globe Euro-Chlor Valves are commonly used in applications where reliable sealing, precise control, and resistance to corrosive and abrasive media are required. Typical applications include chemical processing, petrochemical plants, pharmaceuticals, and refineries.

- What are the benefits of using one?

The benefits of using a Bellow Seal Globe Euro-Chlor Valve include superior sealing performance, reduced maintenance costs due to minimized leakage, enhanced safety, and prolonged service life of the valve and associated equipment.

- What materials are used in their construction?

Bellow Seal Globe Euro-Chlor Valves are typically constructed using high-quality materials such as Carbon Steel, Stainless Steel, or Alloy materials to ensure durability, corrosion resistance, and compatibility with various operating conditions.

- How do I choose the right one for my application?

Choosing the right Bellow Seal Globe Euro-Chlor Valve involves considering factors such as operating pressure, temperature, fluid compatibility, flow rate, and environmental conditions. Consulting with a knowledgeable valve supplier or engineer can help you select the most suitable valve for your specific application.

- Can they be repaired?

Yes, Bellow Seal Globe Euro-Chlor Valves can often be repaired. However, the feasibility of repair depends on the extent of damage and the availability of replacement parts. Consulting with a qualified valve technician or manufacturer is recommended for proper assessment and repair.

- What maintenance is required?

Regular maintenance of Bellow Seal Globe Euro-Chlor Valves typically involves inspection, lubrication, and replacement of worn or damaged components. Following manufacturer guidelines and scheduling routine maintenance checks can help ensure optimal performance and longevity of the valve.

- Are they available in different designs?

Yes, Bellow Seal Globe Euro-Chlor Valves are available in various designs to suit different applications and preferences. Common variations include different sizes, pressure ratings, end connections, and actuation methods.

- Why is Freture the best place to buy from?

The manufacturing of Bellow Seal Globe Euro-Chlor Valves is governed by industry standards, such as MSS SP-117 and API 623, ensuring quality, reliability, and adherence to specified design and performance criteria.

Industries where Bellow Seal Globe Euro-Chlor Valve is Used

Chemical Processing

Petrochemical Industry

Pharmaceutical Industry

Refineries

Water Treatment Industry

Applications of Bellow Seal Globe Euro-Chlor Valve:

- Chemical processing: Handling corrosive chemicals.

- Petrochemical refineries: Controlling volatile substances.

- Pharmaceutical manufacturing: Ensuring contamination-free processes.

- Power generation: Managing high-pressure fluids.

- Water treatment: Efficient flow control, minimizing leakage.