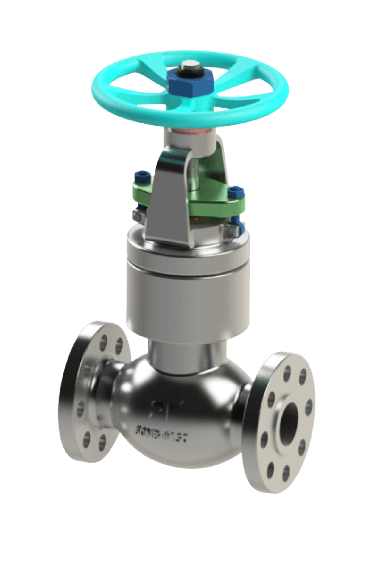

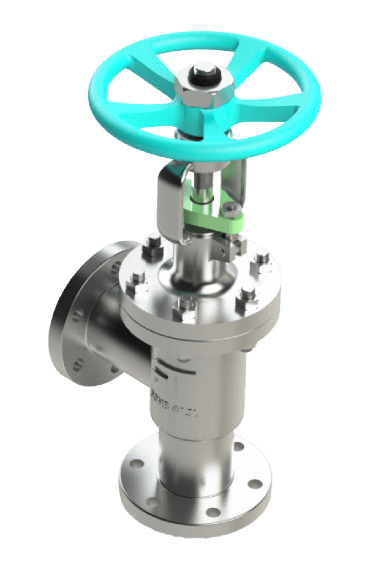

An API globe valve is designed and manufactured according to standards set by the American Petroleum Institute (API), for reliability, durability, and performance in demanding industrial applications, particularly in the oil and gas sector.

API Globe Valve

Standard of Perfection: API Globe Valve

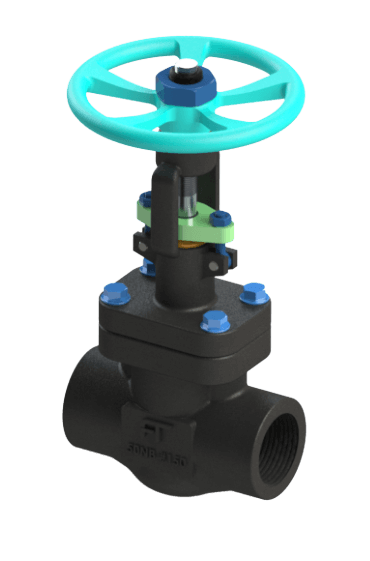

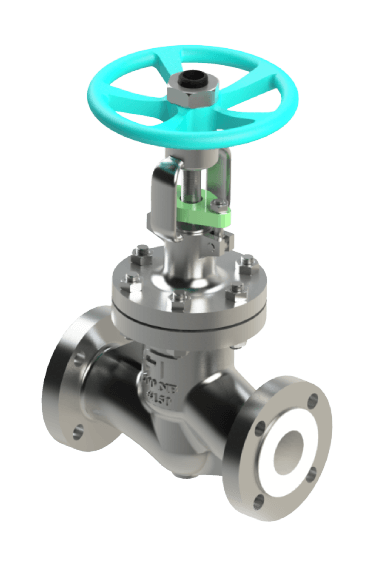

An API globe valve is an internationally recognized valve for highly industrial applications in fluid flow. Designed according to American Petroleum Institute (API) standard, specifically API 600 for manufacturing, API 623 for larger bore valves, and API 602 for small bore valves, these globe valves are robust and reliable.

Freture provides API globe valves to oil and gas production, refining, power generation, and chemical processing industries, where they are utilized for high throttling or frequent operations, ensuring safety and efficiency. With a globe-shaped body and an internal mechanism that moves a plug against the flow to regulate fluid, they allow for precise control of flow rate and provide good shutoff in any flow operation.

Specifications | Features |

|---|---|

Type: API Globe Valve End Connection: Flanged, Threaded, Socket, Butt Weld (ASME B16.5 / B16.11 / B16.25 / ANSI 1.20.1) Size: 15NB - 600NB Class: 150# - 2500# Temperature: -29°C to 593°C (-20°F to 1100°F) Material: Carbon Steel, Stainless Steel, Alloy Steel, Cast iron, etc. Design Standard: API 623 / API 602 / BS 1873 Leakage Rate: ANSI/FCI 70-2 Class IV, V, VI Seat: Stainless Steel, Stellite, Tungsten Carbide, etc. Safety: BS/EN, NACE, API 598 Rev 2009, ISO 5208, and API 607 Rev 2010 | Spherical Body Design: Characteristic shape that gives the valve its name. Versatile Flow Control: Suitable for both throttling and isolation applications. High Pressure Rating: Capable of withstanding high-pressure environments. Corrosion Resistance: Suitable for corrosive fluids and environments. Linear Flow Characteristic: Provides precise flow regulation. Good Shutoff Capability: Effective sealing to prevent leakage. Long Service Life: Durable construction for an extended operational lifespan. Safety Features: It helps prevent accidents and protects equipment from damage due to reverse flow. |

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is an API Globe valve?

- How do they work?

API globe valves work by using a movable disk (or plug) and a stationary ring seat to control the flow of fluids through a system.

- What materials are used in their construction?

They are constructed from high-quality materials such as stainless steel, carbon steel, and alloy steel, ensuring durability, corrosion resistance, and compatibility with various process fluids.

- What are the main applications?

These are widely used in industries such as oil and gas, petrochemicals, power generation, and chemical processing for flow regulation, isolation, and throttling applications.

- Are API Globe Valves suitable for corrosive environments?

Yes, as they come with corrosion-resistant coatings or linings, making them suitable for use in corrosive environments encountered in chemical processing and water treatment plants.

- What testing standards are applied ?

API Globe Valves undergo rigorous testing according to API 598 standards to ensure high performance, tight sealing, and reliability before being put into service.

- What maintenance is required?

Maintenance of API Globe valves includes inspection, lubrication of moving parts, and periodic gland repacking to ensure proper functioning and extend operational lifespan.

- Can they be repaired?

Yes, API Globe valves can typically be repaired. Common repairs include replacing worn-out parts like seals, packing, and trim components to restore functionality and extend the valve's service life.

- How do I choose the right one for my application?

Consider factors like flow rate, pressure and temperature conditions, fluid characteristics, and environmental factors.

You can also connect, with experts here for a free consultation.

- Why is Freture the best place to buy from?

Freture Techno excels in API Globe valves due to high-quality materials, precision engineering, reliable performance, and adherence to API standards, ensuring durability and efficient flow control for industrial applications.

Industries where API Globe Valve is Used

Oil and Gas Industry

Petrochemical Industry

Power Generation Industry

Chemical Processing

Water Treatment System

Applications API Globe Valve

- Flow Regulation: Used for precise flow regulation in various industries.

- Isolation: Effective for complete shut-off of fluid flow when necessary.

- Throttling: Suitable for controlling flow rates by adjusting the valve disc.

- Boiler Feedwater Control: Essential for controlling feedwater flow into boilers in power plants.

- Water Treatment: Utilized for flow regulation and control in water and wastewater treatment plants.