2 Way Manifld Valve are one of the safest and most efficient valves available. The fact that highly sensitive industries like oil and gas and chemical manufacturing companies use it extensively is proof that it’s 100% safe and reliable.

2 Way Manifold Valves

2 Way Manifold is designed specifically for low, medium & high-pressure requirements.

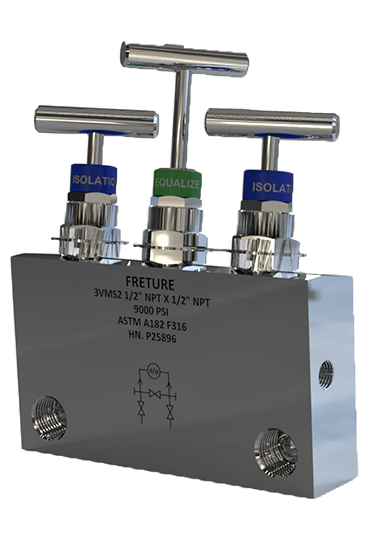

We are a leading 2 Way Manifold Valves manufacturer in Mumbai, India, providing high-performance manifold solutions tailored for various industrial applications. Our 2 Way Manifold Valves for pressure gauges, commonly referred to as block and bleed valves, are designed to deliver accurate pressure control and testing in conjunction with pressure generators. These valves play a crucial role in maintaining system integrity by ensuring precise pressure readings and isolation when required.

One of the standout features of 2 Way Manifold Valves is their compact design, which effectively reduces installation costs and minimizes the number of connections needed in a system. This not only enhances the overall efficiency of the operation but also reduces potential leak paths, contributing to a safer and more reliable setup.

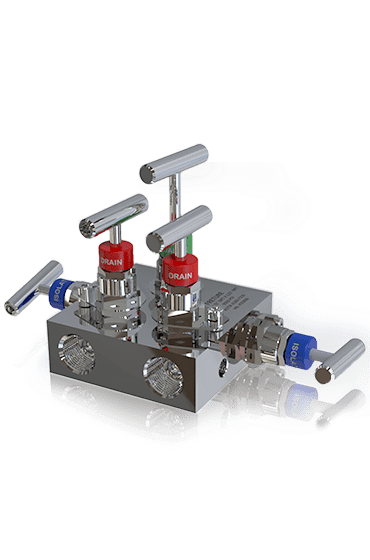

These valves are engineered to be compact in size, effectively reducing costs and minimizing connections. Additionally, 2 Way R Type Manifold Valve is specifically designed for the remote installation of differential pressure transmitters, ensuring seamless and efficient operation in various industrial applications.

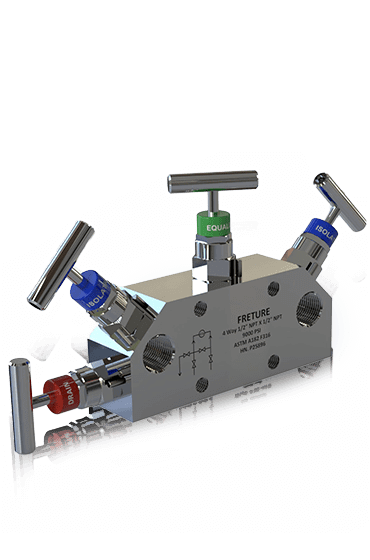

Our 2 Way Manifold Valve R Type is specifically engineered for remote installations, particularly for use with differential pressure transmitters. This allows for seamless operation in situations where direct access to pressure measurement points may be challenging. The R type manifold ensures that the pressure transmitter can function efficiently and accurately in a variety of environments, from oil and gas refineries to chemical processing plants.

In addition to the R type, we offer a variety of other configurations such as E, T, H, S, and Coplanar manifold types. Each is designed to meet specific application needs, ensuring optimal performance whether used for pressure measurement, isolation, or bleeding functions. The versatility of these manifolds valves makes them suitable for industries requiring precise pressure monitoring, control, and maintenance.

At our manufacturing facility in Mumbai, we prioritize quality and precision engineering. All two Way Manifold Valves adhere to stringent industry standards, ensuring reliability and durability in even the most demanding conditions. Whether you need a solution for pressure testing or an advanced manifold system for remote installations, 2 way manifold valves offer the perfect combination of performance, reliability, and cost-efficiency. For premium-quality manifold solutions, trust our expertise in delivering products tailored to meet your exact industrial requirements.

Description | Features |

|---|---|

TYPE: 2 valve Manifold Manifold Valves (R / E / T / H / S/ Coplanar) End Connection: Flange / Butt Weld Size: 15 NB - 300 NB Pressure Rating: 150PSI - 6,000PSI Temperature Range: -7Deg C to 280 Deg C Body Materials: Stainless Steel / Carbon Steel / Alloys Design Standard: MSS Sp99 End Connection Std.: ASME B16.5 / B16.11 / B16.25 / ANSI 1.20.1 Face to Face: ASME B16.10 Rev 2009 Fire safe design: API-607 Rev 2010 Testing: API 598 Rev 2009 Sour Service: NACE MOR 0175 Rev 2009 Documents: BS/EN 10204-3.1 REV 2004 |

|

Related Products

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- Are 2 Way Manifld Valve safe?

- Do I really need a 2 Way Manifld Valve for my factory?

If you are in one of the following industries, a 2 Way Manifld Valve will definitely help you improve the efficiency and safety.

- Chemical Manufacturing

- Oil & Gas Refineries

- Boiler / Reactor Manufacturing

- EPC Contractor company

- Local Traders

If you’re from another industry looking for more details about how you can benefit from using a 2 Way Manifld Valve, please get in touch with us here for further discussion.;

- How does it work?

A 2 Way Manifld Valve functions by directing the flow of fluids from one inlet to two outlets, or from two inlets to one outlet, depending on the specific configuration. This enables the user to control the flow direction and distribution according to the application requirements.

- What are the main applications?

2 Way Manifld Valve find widespread applications in industries such as oil and gas, chemical processing, water treatment, and pharmaceuticals. They are commonly used in flow control systems, pressure measurement, level monitoring, and fluid distribution processes.

- What are the benefits of using one?

The benefits of using a 2 Way Manifld Valve include versatility in fluid control, compact design, simplified piping arrangements, enhanced system efficiency, and improved control over fluid distribution. They also enable easier maintenance and troubleshooting of fluid systems.

- What materials are used in their construction?

2 Way Manifld Valve are typically constructed from materials such as stainless steel, brass, or carbon steel, depending on the specific application requirements. These materials are chosen for their durability, corrosion resistance, and compatibility with various fluids and operating conditions.

- Can they be repaired?

Yes, 2 Way Manifld Valve can often be repaired. Maintenance and repair may involve replacing worn components, such as seals or valves, and ensuring proper calibration to restore functionality.

- Are they available in different designs?

Yes, 2 Way Manifld Valve are available in various designs and configurations to suit different application requirements. These designs may include different port sizes, connection types, and valve arrangements to accommodate specific fluid control needs.

- How do I know which type of 2 Way Manifld Valve is ideal for me?

Get in touch with us here and an expert from Freture Techno will help you decide.

- Why is Freture Techno the best place to buy 2 Way Manifld Valve from?

Most of the time our clients are local hence we are easily accessible

Our 2 Way Manifld Valve are manufactured & Tested as per international Std. & we offered only best quality product

We will keep stock of Std. Product for last minute urgency

We provide products only from reputed & highly reliable manufactured

We have an experienced technical team who will be able to understand client’s exact requirements & accordingly we will offer solutions.

Industries where Two Way Manifold Valve is used

Chemical Manufacturing

Oil & Gas Refineries

Pharmaceutical Industry

Water Treatment Industry

HVAC System

Applications of 2 Way Manifold Valves

Pressure Testing: They are commonly used in pressure testing applications, allowing precise control and measurement of fluid pressure.

Instrumentation: They are essential for connecting pressure gauges and other instrumentation to process lines, providing accurate pressure readings for monitoring and control.

Fluid Distribution: They distribute fluids from a single source to two separate destinations, enabling efficient flow management in various industrial processes.

Isolation: They facilitate the isolation of pressure gauges and other instruments from the process line, allowing for maintenance or replacement without interrupting system operations.

Pressure Regulation: They regulate and maintain consistent pressure in fluid systems, ensuring optimal performance of connected components and processes.