A condensate pot is a vessel placed in a steam line to collect condensate. It acts as a barrier between the steam line and sensitive instruments, preventing damage or inaccuracies that could result from direct contact with steam or condensate.

Condensate Pot

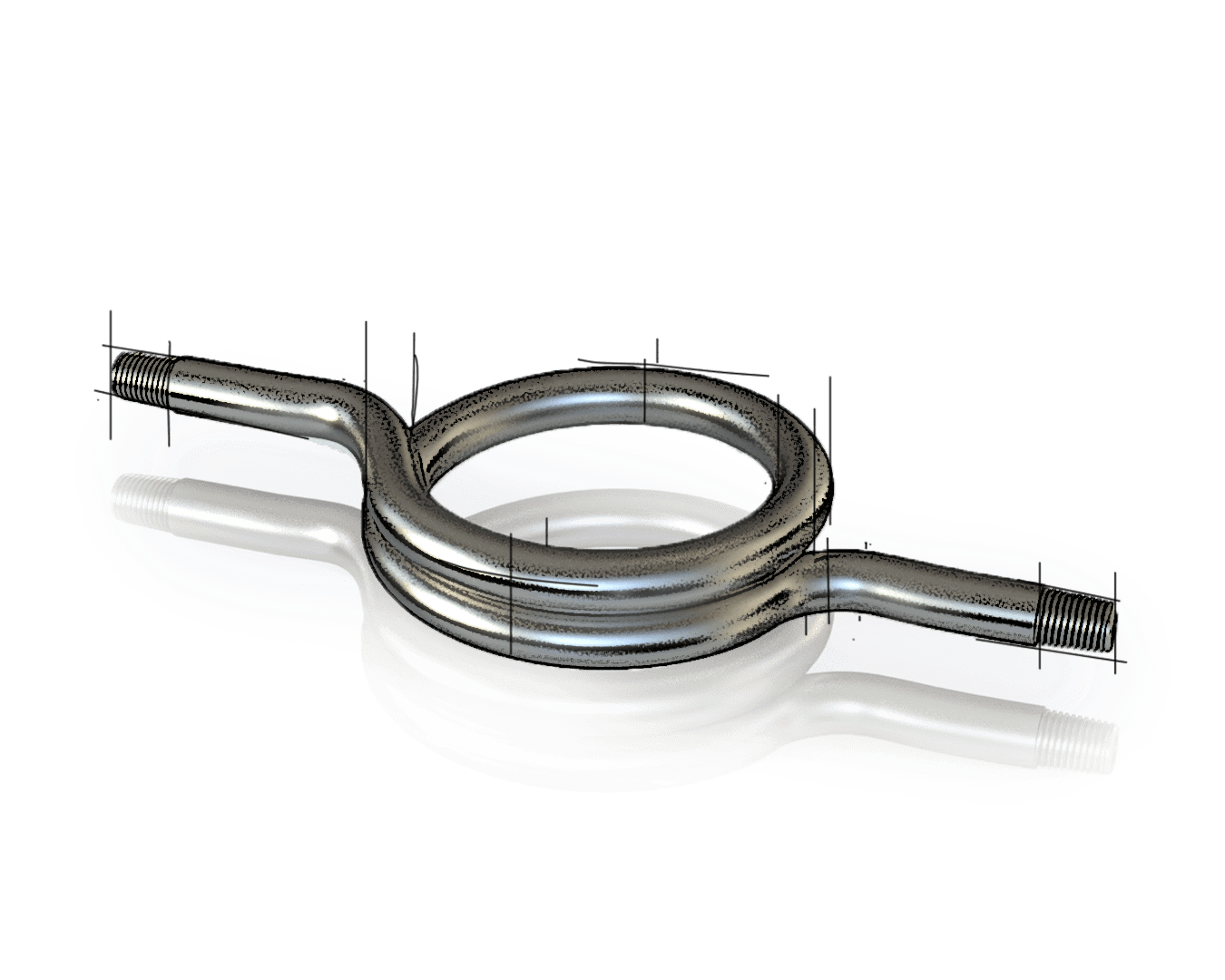

Precision-engineered condensate pots for superior performance and longevity

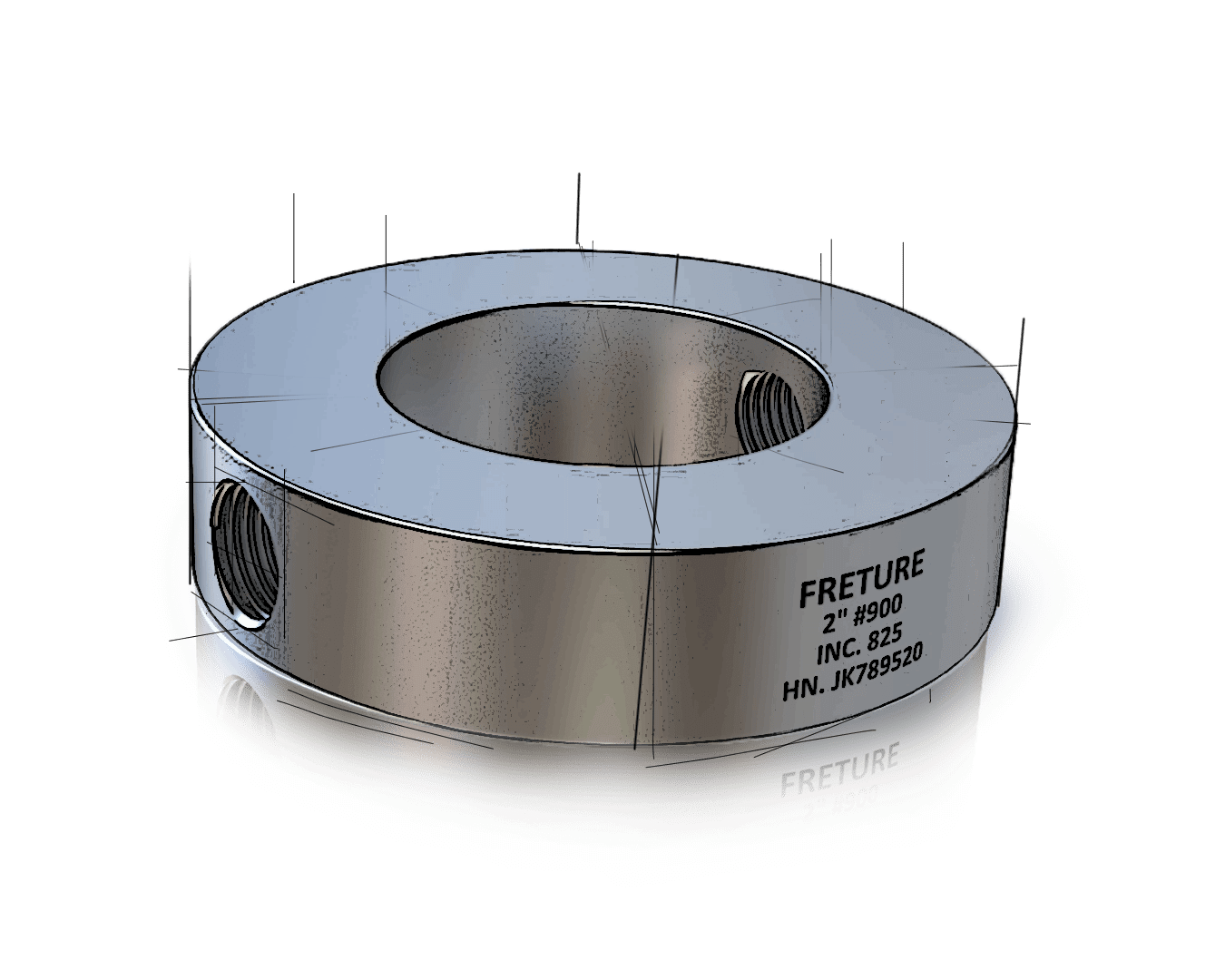

As experienced condensate pot manufacturers in Mumbai, India, Freture understands the critical role these components play all industrial systems.Our expertly designed condensate pots act as reservoirs that capture and hold condensate—liquids formed when gases cool and condense during processes like steam generation or gas transportation.Which prevents condensate from entering and potentially damaging critical instrumentation and control equipment by allowing for the separation and drainage of liquids.

By maintaining the integrity of measurement devices, they ensure accurate readings and stable operation, which is crucial for maintaining process efficiency and safety. In addition, they also reduce the risk of corrosion and other issues related to moisture accumulation in pipelines and equipment. With this reliability and protection, which extend the lifespan of industrial components, Freture's condensate pots are an invaluable part of industrial processes.

Specifications | Features |

|---|---|

Type: Condensate Pot ( Remote Mount or Direct Mount ) Size Range: 2" to 6" End Connection: Thread type (NPT, BSPP, BSPT) / Butt Weld / Socket Weld (ASME B16.5 / B16.11 / B16.25 / ASME B1.20.1.) Pressure Rating : 6000 psi Temperature Range : Upto 300 °C Body Material : Stainless Steel / 316SS / Carbon Steel / Alloys Design Standard: ASME B31.1 & B31.3, ASME Section VIII Insulation Thickness: 1" to 3" (optional, based on application needs) Capacity: 0:5 to 10 liters Safety: BS / EN 10204-3.1 REV 2004, NACE, API 598 Rev 2009, API 607 Rev 2010 | Protects equipment : removes condensate and debris to prevent corrosion, erosion, and malfunction. High Capacity : Sized to handle the expected condensate volume. Inlet and Outlet Connections: Available in threaded (NPT), flanged, socket weld, or butt weld options. Vent and Drain Ports : Additional connections for venting and draining. Compact Design : Space-saving and easy to install. Heating Elements : Optional electric or steam tracing for cold environments. Versatile Application : Suitable for a wide range of fluids including gases and liquids. Safety/Insulation Factor : Designed with a safety margin as per relevant standards,with an insulation option. |

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is a condensate pot?

- Why are they used?

Condensate pots are used to protect instruments such as pressure transmitters, flow meters, and temperature sensors from the harmful effects of direct exposure to high-pressure steam or condensate. They help maintain instrument accuracy and prolong their lifespan.

- What are main applications of it?

While condensate pots are primarily used in steam systems, they can also be employed in other applications where condensation or liquid separation is necessary, such as in gas pipelines or refrigeration systems.

- What materials are they made of?

Condensate pots are often made of materials such as stainless steel, carbon steel, or exotic alloys, depending on the specific application requirements. These materials are chosen for their corrosion resistance and durability in high-pressure steam environments.

- When should condensate pots be used?

Condensate pots should be used whenever sensitive instruments are installed in steam systems. They are especially important in applications where accurate measurement or control is critical, such as in power plants, refineries, and chemical processing facilities.

- How they are installed?

Condensate pots are usually installed vertically below the instrument they protect, with appropriate drain and vent connections. Proper orientation and sizing are crucial to ensuring effective condensate removal and instrument performance.

- Can a extend the lifespan of my equipment?

Yes, by preventing moisture-related damage, condensate pots help extend the lifespan of industrial components.

- How does they help in safety?

By maintaining the integrity of measurement devices and preventing condensate-induced issues, condensate pots help ensure safe and efficient industrial operations.

- Does they need Maintainance?

Although they are easy to maintain, regularly inspecting for leaks, ensuring drains are clear, and periodically flushing to remove debris can increase its lifetime.

- Why is Freture the best place to buy from?

quality products, competitive pricing, and excellent customer service. With a wide range of options, reliability, and technical expertise, they provide convenience and support throughout the purchasing process and beyond

Industries where Condensate Pot is used

Chemical Manufacturing

Oil & Gas Refineries

Pharmaceutical Industry

HVAC Systems

Power Generation

Applications of Condensate Pot

- Oil & Gas Industry : They are applied in oil and gas production facilities to manage condensate from pipelines and maintain accurate pressure measurements in flow meters and gauges.

- Steam Systems : They are used to collect condensate from steam lines, ensuring efficient removal of water and preventing water hammer.

- HVAC Systems : In heating, ventilation, and air conditioning systems, condensate pots are used to collect condensate from cooling coils and prevent water buildup.

- Refineries : They are utilized in refineries to manage condensate from steam lines and maintain optimal operating conditions for process equipment.

- Chemical Processing : In chemical plants, They are used to trap condensate and maintain a barrier between the process fluid and sensitive instruments or valves.