A Floating Ball Valve is a type of quarter-turn valve in which the ball is not fixed in place, allowing it to float within the valve body.

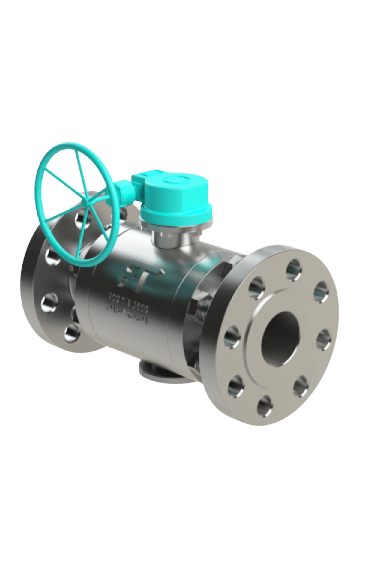

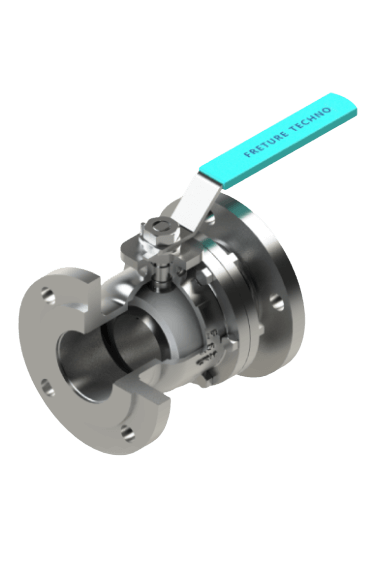

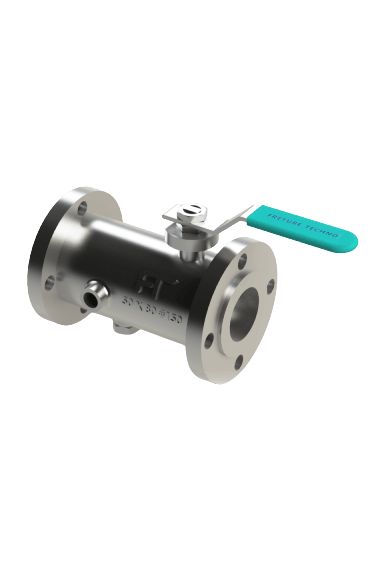

Floating Ball Valve

Ball Valves: Precision in Flow Control

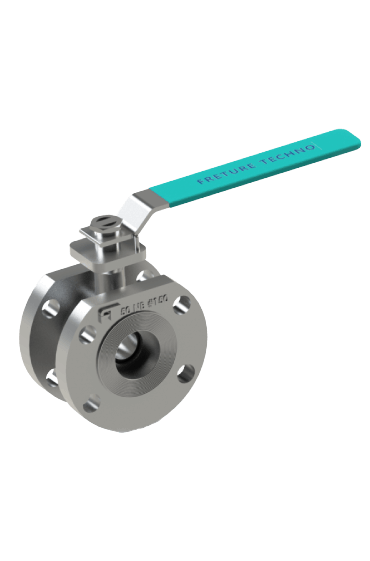

Freture Techno, a renowned Floating Ball Valve manufacturer in Mumbai, India, brings you a range of cutting-edge solutions for fluid control. Our Floating Ball Valves stand as a testament to precision engineering, ensuring reliable performance in various industries and applications.

Floating Ball Valve: Engineered Excellence

Key Features:

- Optimized Design: Our Floating Ball Valves are meticulously designed to provide smooth, low-torque operation, reducing wear and enhancing longevity.

- Seal Reliability: The floating ball design ensures a secure and reliable seal, minimizing leakage risks even under high-pressure conditions.

- Material Versatility: Available in a variety of materials, including stainless steel, carbon steel, and alloy options, to match your specific fluid compatibility and corrosion resistance needs.

- Size Range: From small-scale applications to heavy-duty industrial needs, our Floating Ball Valves are available in various sizes to meet diverse requirements.

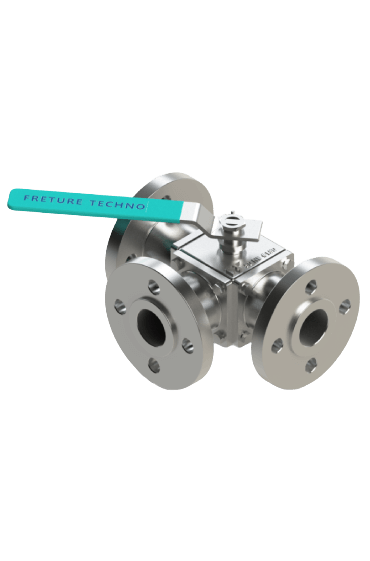

- End Connections: Choose from a range of end connections, including threaded, flanged, and socket weld, for seamless integration into your pipeline system.

- Industry Compliance: Our Floating Ball Valves adhere to international standards and certifications, ensuring quality, safety, and performance excellence.

Why Choose Freture Techno for Floating Ball Valves?

With Freture Techno, you gain:

- Engineering Expertise: Benefit from our extensive knowledge and experience in fluid control solutions.

- Custom Solutions: We tailor Floating Ball Valves to your specific needs, ensuring a perfect fit for your applications.

- Global Reach: As a trusted manufacturer, we serve clients not only locally but also worldwide. Quality Assurance: Our Floating Ball Valves undergo rigorous testing, guaranteeing unmatched reliability.

- Competitive Pricing: Enjoy cost-effective solutions without compromising on quality. Make Freture Techno your partner for Floating Ball Valves, and experience precision, reliability, and excellence in fluid control. Contact us today to explore how our Floating Ball Valves can elevate your operations.

Description | Features |

|---|---|

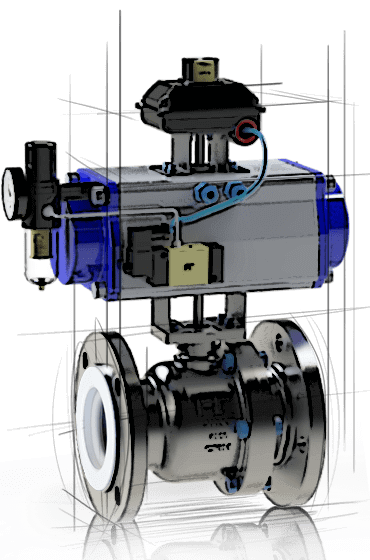

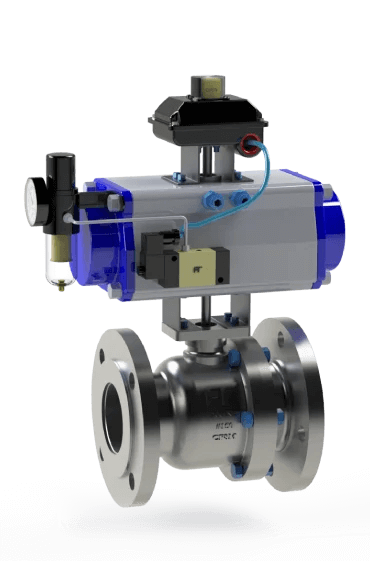

Type: Floating Ball Valve Size: 15NB - 300NB End Connection: Flange / Buttweld/ Socket Weld / screwed class : 150# - 2500# Temperature Range: -7Deg C to 280 Deg C Body Materials: Stainless Steel / Carbon Steel / Alloys Design Std.: API 6D | ISO 17292 / ASME B16.34 / API 607 End Connection Std.: ASME B16.5 / B16.11 / B16.25 / ANSI 1.20.1 Face to Face: ASME B16.10 Rev 2009 Operation: Manual & Actuated (Rack & Pinion / Scotch Yoke / Electric) Gear Operated Fire safe design: API-607 Rev 2010 Testing: API 598 Rev 2009 Sour Service: NACE MOR 0175 Rev 2009 Documents: BS/EN 10204-3.1 REV 2004 |

|

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is a Floating Ball Valve

- How does it work?

The ball in a Floating Ball Valve is held in place by two seats, one on the upstream side and one on the downstream side. When the valve is closed, the fluid pressure pushes the ball against the downstream seat, creating a seal.

- What are the main applications?

Floating ball valves are widely used in industries like oil and gas, petrochemicals, water treatment, and power generation for on/off and throttling control.

- What are the benefits of using one?

Benefits include excellent sealing, minimal pressure drop, easy operation, versatility, reliable shut-off, and resistance to leakage.

- What materials are used in their construction?

Materials include stainless steel, carbon steel, brass, bronze, and various alloys, chosen based on fluid compatibility, temperature, and pressure.

- How do I choose the right one for my application?

Choose based on fluid type, operating pressure/temperature, flow rate, valve size, end connections, and environmental conditions. Seek advice from a qualified supplier or engineer.

- Can they be repaired?

Yes, they can be repaired by replacing worn seals, seats, or other internal components, following proper procedures and using compatible parts.

- What maintenance is required?

Regular maintenance includes inspection, lubrication, leak checks, and component replacement following manufacturer's recommendations.

- Are they available in different designs?

Yes, they come in various designs including two-piece, three-piece, and top-entry configurations with different end connections.

- Why is Freture the best place to buy from?

Freture offers high-quality, industry-standard products designed for superior performance, reliability, and durability, backed by excellent service and support.

Industries where Floating Ball Valve is Used

Oil and Gas Industry

Petrochemical Industry

Chemical Processing

Power Generation

Pharmacutical Industry

Applications of Bellow Seal Valve

- On/off Control: They are commonly used for on/off control of fluid flow in pipelines and process systems.

- Throttling Control: They are utilized for precise throttling of fluid flow, regulating the rate of flow through the system.

- Isolation: They are employed to isolate sections of pipelines or process systems for maintenance or repair.

- High-Pressure Applications: They are suitable for high-pressure applications due to their robust construction and excellent sealing properties.

- Versatile Media Handling: They are used for handling a wide range of media, including liquids, gases, and slurries, making them versatile across various industries.