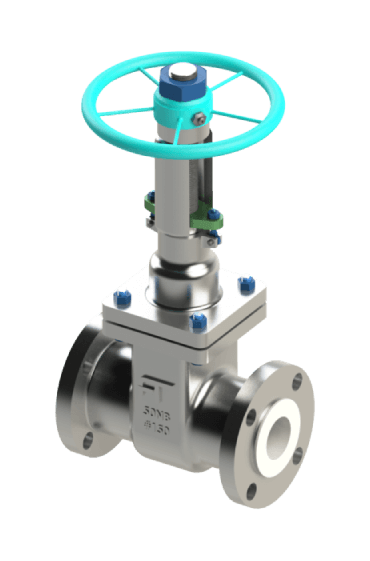

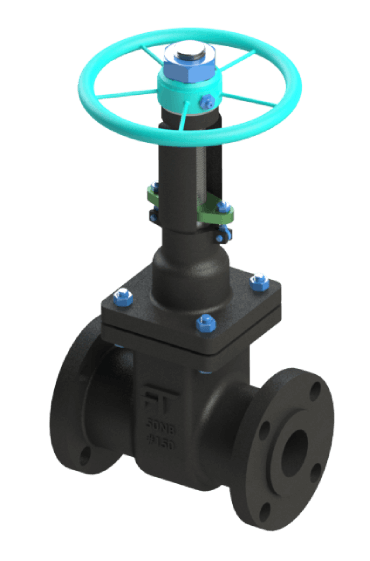

A Forged Gate Valve is a type of valve used to control the flow of fluid by lifting a gate out of the fluid path, made from forged materials for enhanced strength and durability.

Forged Gate Valve

They are made with the highest quality components and under the strict supervision of professional quality controllers.

Freture Techno is among the leading API 602 Forged Gate Valve manufacturers in Mumbai, India. We take pride in offering a comprehensive range of high-quality forged gate valves, meticulously designed to excel in various industrial applications.

A forged gate valve is a robust device designed to control the flow of liquids and gases in pipelines. Constructed through the forging process, it offers superior strength and durability compared to cast valves. Featuring a wedge-shaped disc that lifts or lowers to open or close the flow path, forged gate valves ensure minimal pressure drop and optimal flow efficiency. They are ideal for on/off applications in high-pressure and high-temperature environments, making them suitable for oil and gas, chemical processing, and power generation industries. With excellent sealing capabilities, these valves provide reliable performance and longevity in demanding conditions.

The Excellence of Freture Techno Pvt. Ltd.

The Valves represent precision engineering and are meticulously crafted to provide unparalleled performance and long-lasting durability. Here's why they are the preferred choice for fluid control:

- Robust Construction: Crafted from premium materials, our forged gate valves are known for their ruggedness, ensuring they withstand harsh conditions and maintain structural integrity over time.

- Precise Control: The design of our gate valves guarantees accurate and efficient fluid flow control, minimizing pressure drop and preventing leakage.

- Versatility: Our forged gate valves are adaptable to diverse applications across industries, including oil and gas, petrochemical, power generation, and more.

- Unidirectional Flow: Engineered to permit fluid flow in one direction while blocking reverse flow, these gate valves provide enhanced safety and efficiency.

- Low Maintenance: With a user-friendly design and minimal moving parts, our gate valves are low-maintenance, contributing to reduced downtime and operational costs.

- Customization: We offer tailored solutions to meet your specific requirements, from valve size and end connections to materials of construction.

Key Features of Forged Gate Valves

Forged gate valves are designed for high-pressure and high-temperature applications, offering superior strength and durability due to the forging process. They provide reliable, leak-proof sealing, making them ideal for critical industries such as oil and gas, petrochemical, and power generation. Available in various sizes and pressure ratings, they meet global standards like API 602 and ASME B16.10. These valves come in multiple materials, including carbon steel and stainless steel, with options for manual, gear, motorized, or actuated operation, ensuring versatility and safety compliance for demanding industrial environments.

Crafting Quality Valves for Optimal Performance

Choose Freture Techno for your Forged Gate Valve needs, and experience the perfect blend of cutting-edge technology and an unwavering commitment to customer satisfaction. Contact us today to discover how our forged gate valves can elevate your fluid control systems.

Specifications | Features |

|---|---|

Type: Forged Gate Valve End Connection: Screwed End (ANSI 1.20.1) / Socket weld End (B 16.11) Size: 15 NB - 600 NB Class: 150# - 2500# Temperature Range: -7° C to 200° C MOC: Carbon Steel / Stainless Steel / Alloy Design Standard: API 602 Face to Face: ASME B16.10 Rev 2009 Operation: Manual / Gear / Motorised / Actuated Safety: NACE, BS/EN 10204-3.1 REV 2019, API 6FA, API 598 Rev 2009 / ISO 15848 |

|

Related Products

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is a Forged Gate Valve?

- How does it work?

It works by raising or lowering a gate inside the valve body to start or stop the flow of fluid, providing a tight seal when closed.

- What are the main applications?

Main applications include oil and gas, petrochemical, power generation, water treatment, and chemical processing industries.

- What are the benefits of using one?

Benefits include high durability, excellent sealing performance, ability to handle high pressure and temperature, and minimal pressure drop when fully open.

- What materials are used in their construction?

Forged Gate Valves are typically constructed from high-strength materials such as carbon steel, stainless steel, and various alloys to withstand harsh operating conditions.

- How do I choose the right one for my application?

Choose based on factors like fluid type, pressure and temperature requirements, valve size, and compatibility with your specific application needs.

- Can they be repaired?

Yes, it can be repaired by replacing damaged components such as the gate, seals, and stem.

- What maintenance is required?

Regular maintenance includes inspection, cleaning, lubrication of moving parts, and replacing worn or damaged components to ensure reliable operation.

- Are they available in different designs?

Yes, they are available in various designs, including different sizes, pressure ratings, and end connections to meet diverse application requirements.

- Why is Freture the best place to buy from?

Freture offers high-quality Forged Gate Valves, backed by expert engineering, extensive industry experience, and a commitment to customer satisfaction. We provide reliable, competitively priced products tailored to meet your specific needs.

Industries where Forged Steel Gate Valve is Used

Oil and Gas Industry

Petrochemical Industry

Power Generation

Water Treatment

Chemical Processing

Application of Forged Gate Valve

- Flow Control: Regulates the flow of fluids in pipelines by lifting or lowering the gate.

- Isolation: Provides reliable shut-off for isolating sections of a pipeline during maintenance or emergencies.

- High-Pressure Systems: Handles high-pressure applications in industries such as oil and gas and petrochemicals.

- High-Temperature Environments: Suitable for high-temperature operations in power generation and chemical processing.

- Corrosive Fluids: Used in environments where corrosive fluids are present, ensuring durability and long service life.