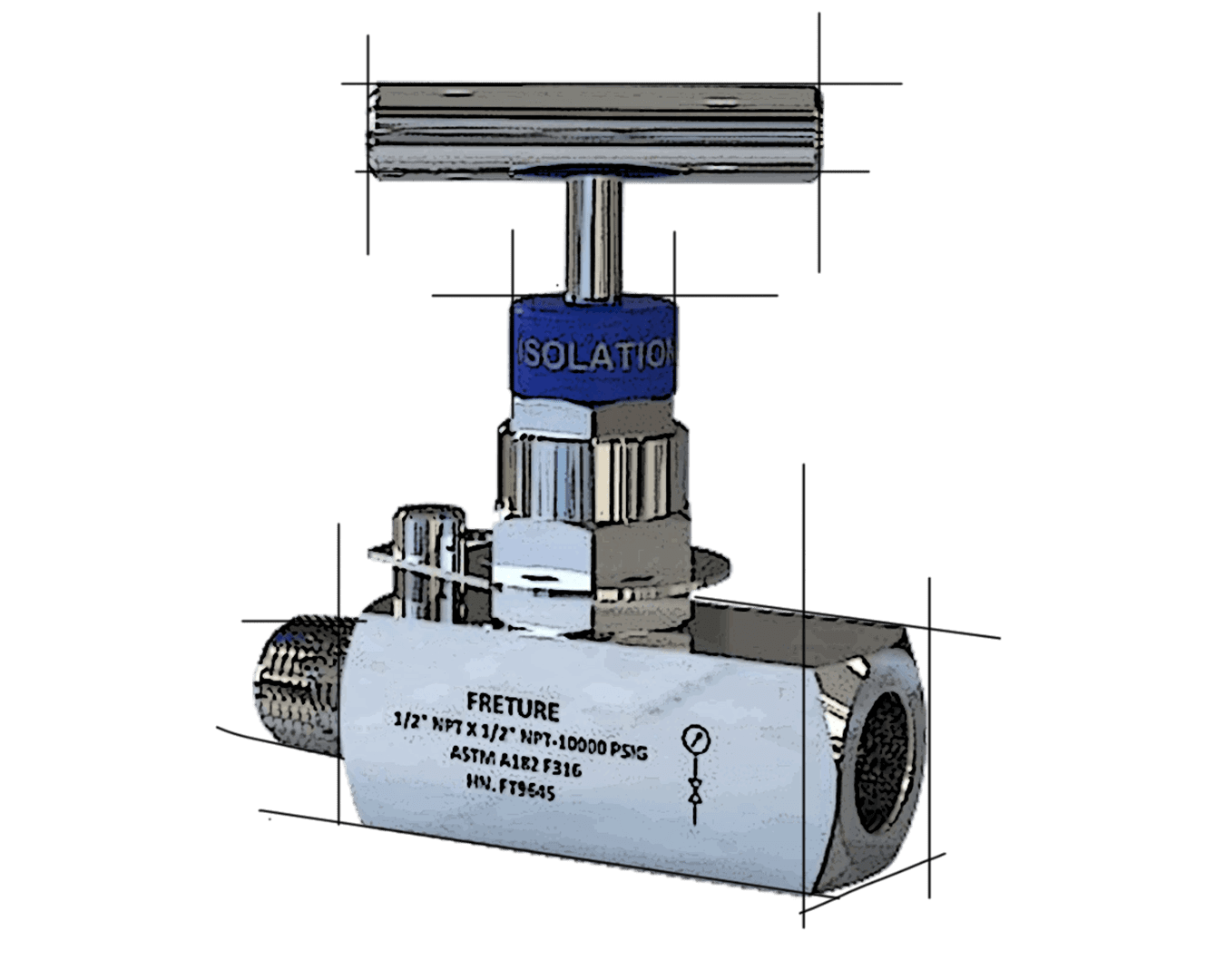

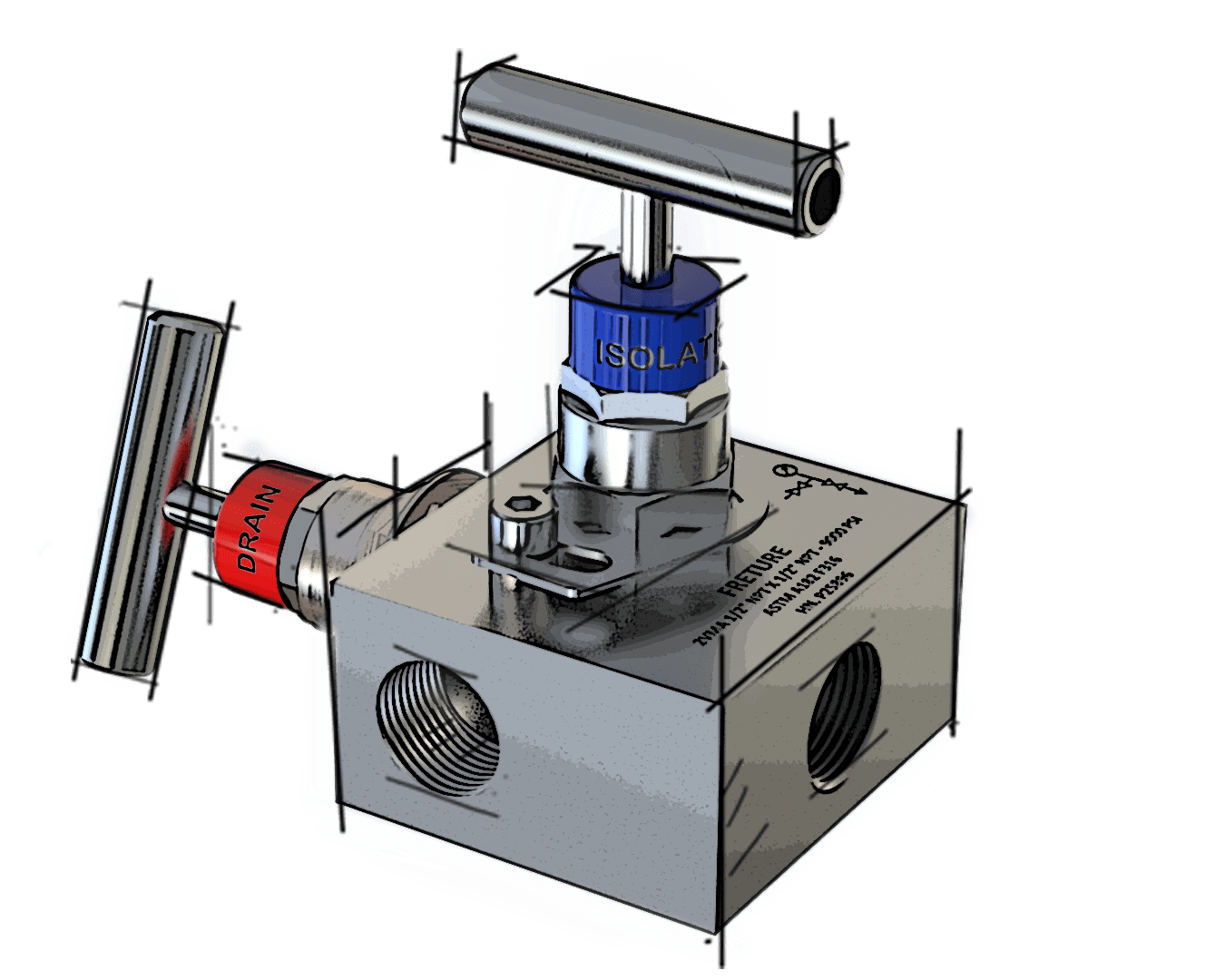

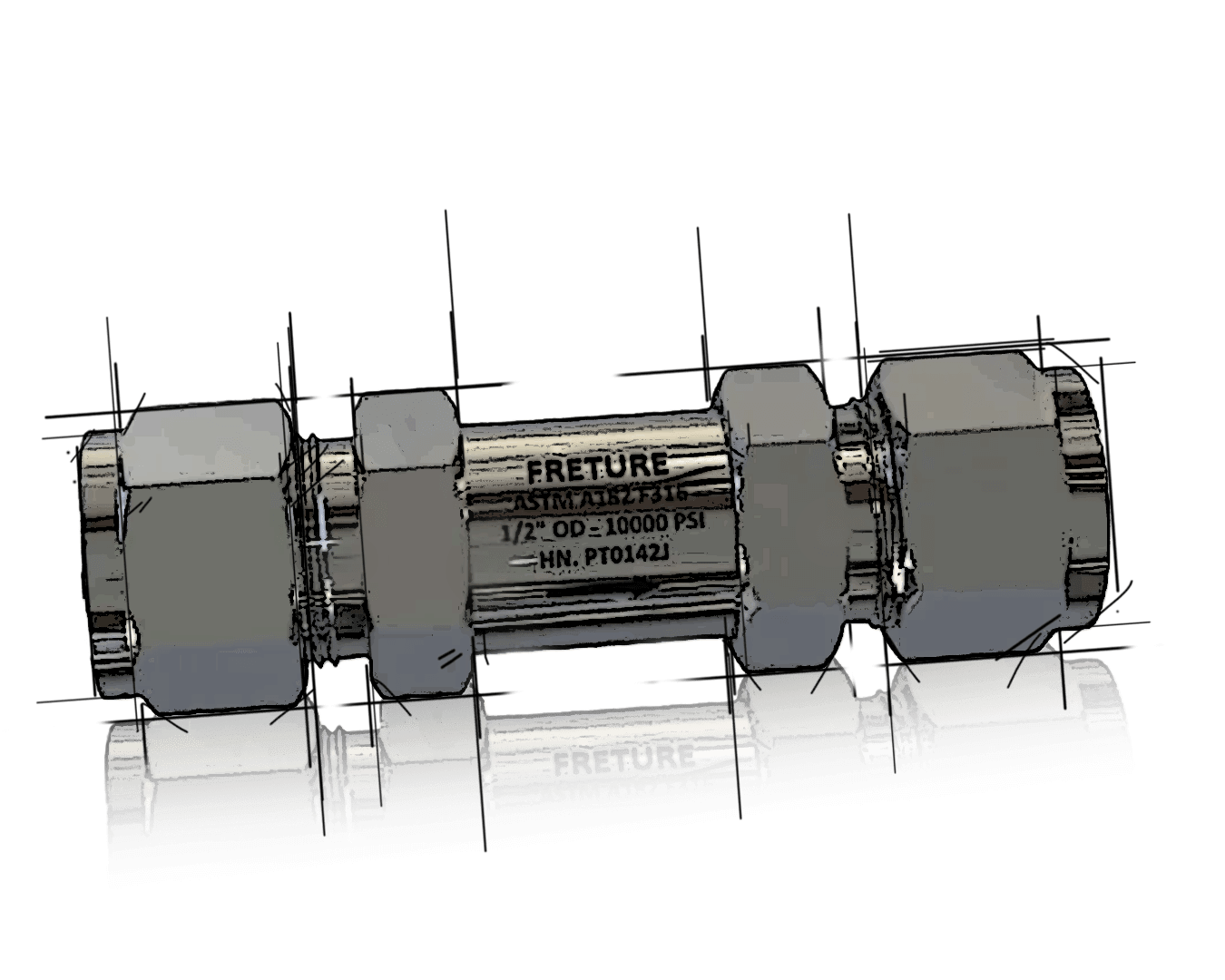

A high-pressure instrumentation check valve is a specialized valve designed to allow fluid or gas flow in one direction while preventing backflow, maintaining system integrity, and ensuring safety in high-pressure environments.

High Pressure Check Valve

Securing Unidirectional Flow with Precision: 15000 psi High Pressure Check Valves

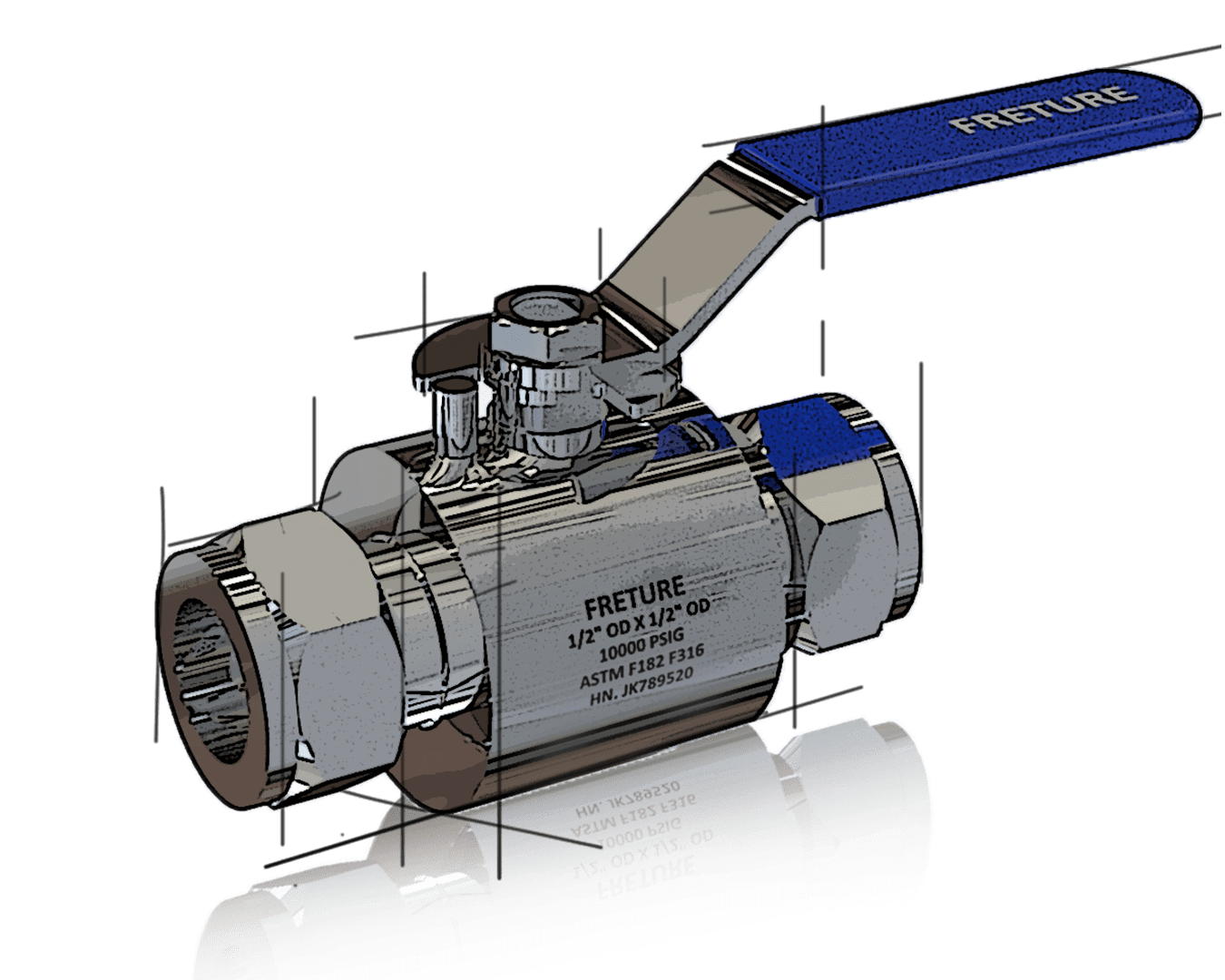

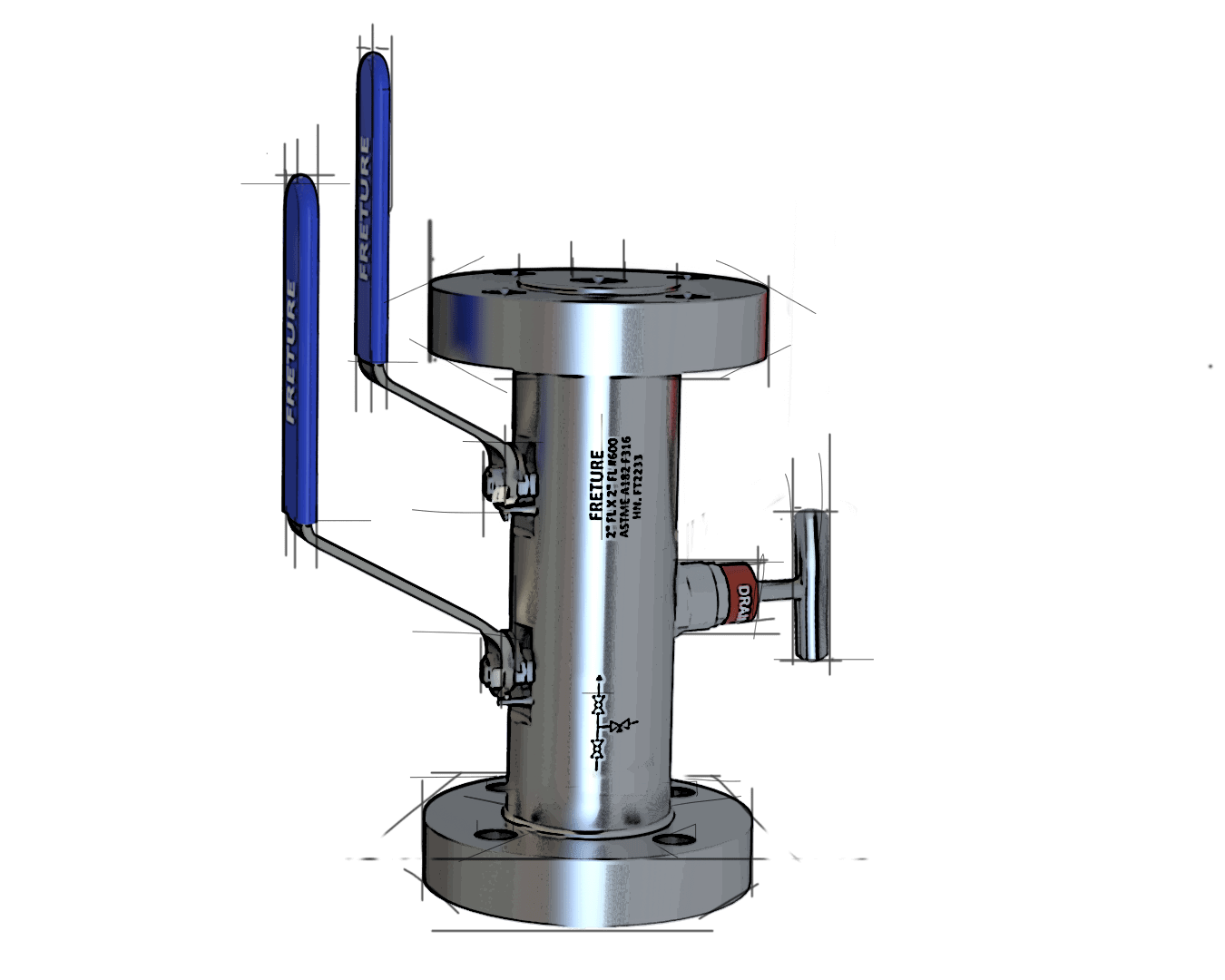

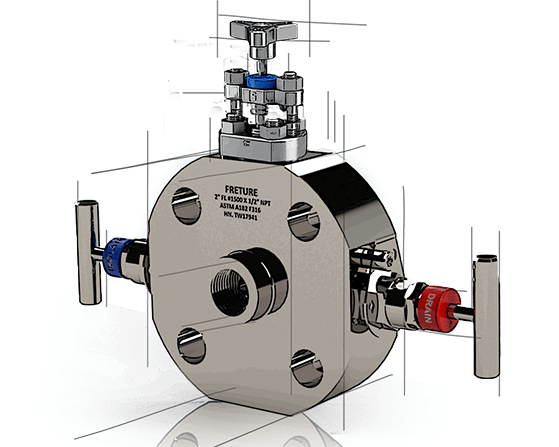

We are a leading High Pressure Check Valve manufacturer in Mumbai, India, also known as one flow direction valve. We specialize in the production of high-quality valves for various industrial applications. High Pressure Check Valves ensure that the medium flows in only one direction, providing unidirectional flow and tight shut-off for liquids and gases with high reliability.

High Pressure Check Valves are meticulously manufactured and designed according to the MSS SP-99 standard, ensuring precision and reliability. Available in Class ratings ranging from 2000 psi to 15000 psi, High Pressure Check Valve are engineered to meet the demanding requirements of various industrial applications. With a focus on quality and performance, high pressure nrv valve provide efficient flow control and secure shutoff, making them ideal for critical process systems in oil and gas, petrochemical, chemical processing, and other industries.

Description | Features |

|---|---|

TYPE: Instrumentation Check Valve End Connection: NPT, BSPT, BSPP, Flange / Butt Weld, Size: 15 NB - 300 NB Pressure Rating: 2000PSI-15000PSI Temperature Range: -65°F to 450°F (-54°C to 232°C). Body Materials: Stainless Steel / Carbon Steel / Alloys Design Standard: MSS SP-99, API 598, ASME B16.34, and ISO 9001 Face to Face: ASME B16.10 Rev 2009 Safety: NACE MOR 0175 , BS/EN 10204-3.1 REV 2004, API 598 Rev 2009, API-607 |

|