It is a device used to clean and maintain pressure measurement instruments by flushing out residues and preventing blockages in process lines.

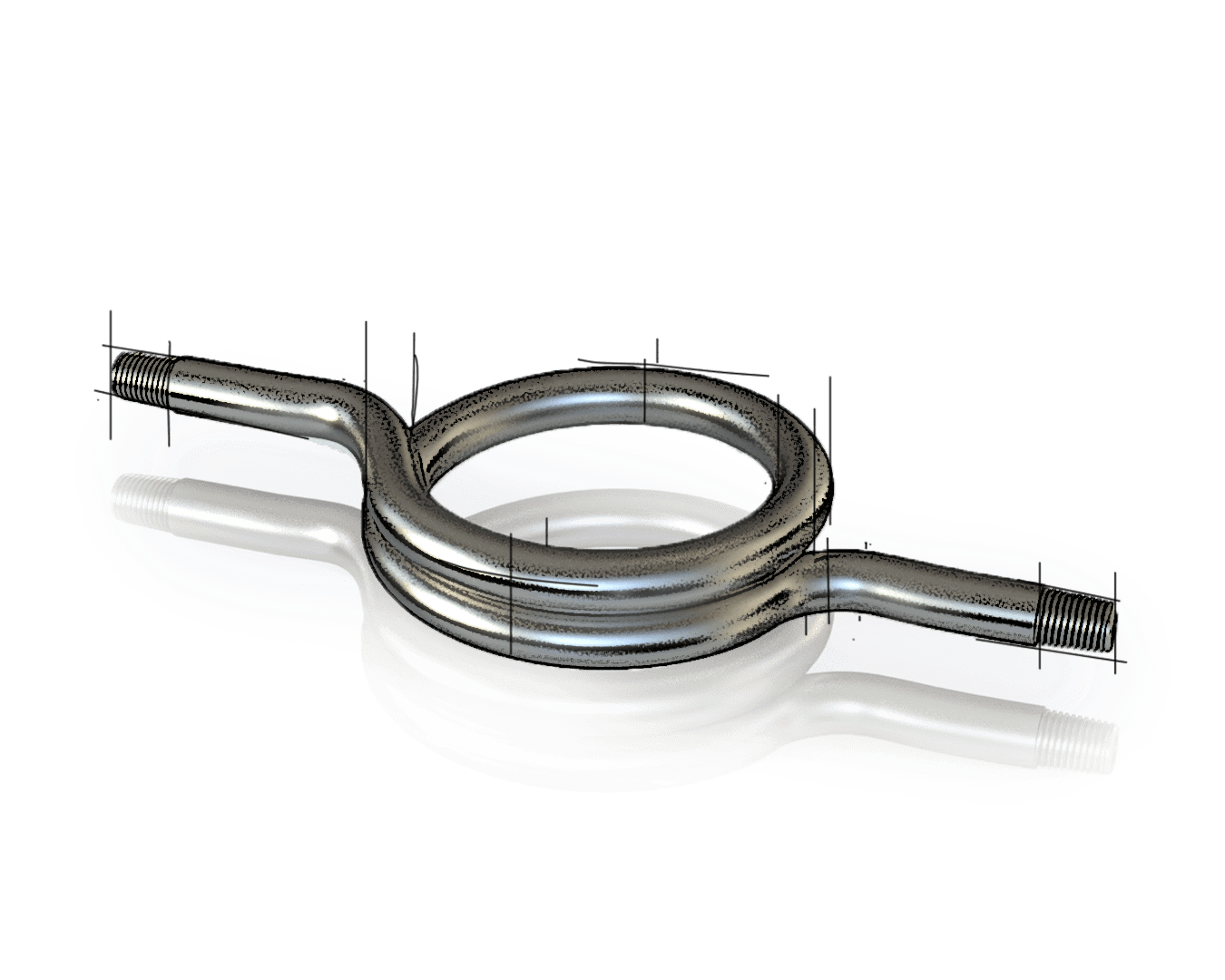

Flushing Ring

flushing ring is mounted between the diaphragm seal

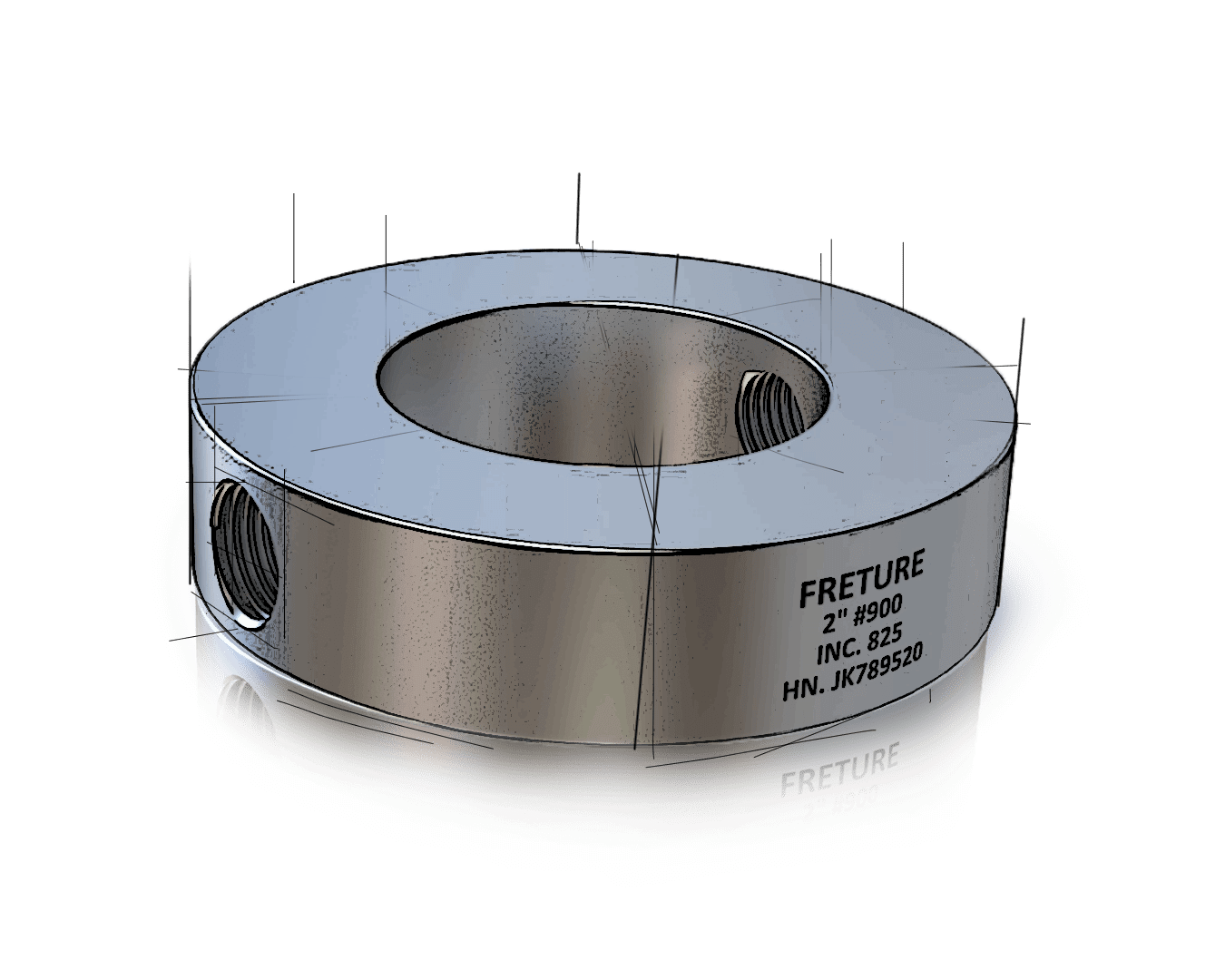

Freture's is prominent leading Flushing Ring manufacturer in Mumbai, India. A flushing ring is a metal donut-shaped component placed between the seal and the customer's process connection. It features threaded ports (¼-inch or ½-inch) for diaphragm surface flushing during cleaning. Flush rings generally adhere to gasket dimensions specified by flange standards like ASME B16.5 or EN 1092-1. In ASME B16.5, for RF facing, dimensions are consistent across pressure classes for a given size. For instance, a 2″ flush ring fits class 150 through 2500 with identical dimensions. However, different facings require unique dimensions per size and rating.

Flushing rings, known by various functional names, share a similar basic design. Positioned between a diaphragm seal and the process nozzle, they are commonly referred to as "Flushing Ring" due to their role in clearing process medium buildup from the diaphragm. These rings typically feature one or two threaded flushing ports on their sides, which can either be plugged or connected to a drainage system. This design allows for system flushing without disconnecting the remote seal from the process flange. The pressure chamber of the flush ring can be vented or drained and filled with cleaning detergent for effective diaphragm cleaning.

Specifications | Features |

|---|---|

Type: Flushing Ring End Connection: Thread type (NPT, BSPP, BSPT) / flanged. Size: 1" to 4" Pressure Rating: 0 to 6000 psi Temperature: upto 482°C Material: Stainless Steel / 316SS / Carbon Steel / Alloys Design Standard: API 6D rev 23, ASME B31.3, API 614 Flushing Hole Diameter: 5 mm to 15 mm Number of Flushing Holes: 1 to 6 Safety: BS / EN, NACE, API 598 Rev 2009, ISO 5208, API 607 Rev 2010 | Custom Designs: Customisation with features like needle valves, shut-off valves, and flanged ends. Size Range: Come in various flange sizes for verstatile applications Flushing & Isolation: Cleans diaphragm & isolates process medium with valves (customizable). Pressure Testing: With MWP 1.5 Testing for reliable at any Pressure. Temperature Tolerance: Extreme temperatures tolerance. Material Selection: Available in various materials for compatibility. Flange Compatibility: Fits various piping (DIN, ANSI, JIS, API). Sealing Options: Configurable sealing surfaces for proper fit. Fire Safety Option: equipped with fire-safe OS&Y shut-off valves as isolation in case of fire. |

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is a flushing ring?

- How do they work?

They are installed in process piping systems to create a flush connection. They allow for the introduction of a cleaning or flushing solution to remove debris or buildup and ensure the proper functioning of equipment such as pressure transmitters or gauges.

- What are they used for?

It also known as drip rings, diaphragm seals, or bleed rings, are used to flush fluids or gases in process systems. They are often employed in conjunction with diaphragm seals to ensure accurate pressure measurements and to prevent clogging or contamination.

- What are the main applications?

They are commonly used in the chemical, petrochemical, oil and gas, pharmaceutical, food and beverage, water and wastewater treatment, power generation, paper and pulp, marine, and mining industries.

- What materials are flushing rings available in?

They are typically available in a range of materials to suit different applications and process conditions. Common materials include stainless steel, Monel, Inconel, Incoloy, and Hastelloy, chosen for their corrosion resistance and durability.

- It is used for venting processes?

Yes, flushing rings can be utilized for venting processes in addition to flushing solutions with diaphragm seals. They provide a convenient point for venting gases or relieving pressure in the system.

- How do I select the right flushing ring for my application?

When selecting a flushing ring, consider factors such as the type of fluid or gas being handled, operating pressure and temperature, pipe size, and compatibility with other system components. Consulting with a knowledgeable supplier or engineer can help ensure you choose the most suitable flushing ring for your specific needs.

- Are they available in different designs?

Yes, it come in various designs and sizes to match different process connections and measurement instruments, including single-hole and multiple-hole configurations.

- What maintenance is required?

They require minimal maintenance, mainly ensuring that the cleaning fluid is compatible and that the connections are secure. Regular checks can help maintain their effectiveness.

- Why is Freture the best place to buy from?

As Flushing ring manufacturers, Freture offers a wide range of high-quality flushing rings, excellent customer service, and expert guidance to help you choose the right product for your application. Their products are competitively priced and made from top-grade materials to ensure durability and performance.

Industries where Flushing Ring is used

Chemical and Petrochemical Industry

Oil & Gas Refineries

Pharmaceutical Industry

Food And Beverage Industry

Water and Wastewater Treatment

Applications of Flushing Ring

- Corrosive Chemical Handling: Prevents clogging in system by flushing out corrosive substances.

Heat Exchanger Cleaning: Removing deposits from heat exchangers to maintain thermal efficiency.

Boiler Systems: Removes sediment build-up from pressure measurement points in steam boilers.

Wastewater Treatment Sensors: Preventing fouling of sensors used in wastewater treatment plants.

- Food Processing Equipment: Cleaning sensors and instruments in food processing lines to ensure hygiene.