A Forged Ball Valve is a type of valve used to control fluid flow in industrial applications. It consists of a spherical ball with a hole through the middle. When the valve is open, fluid can pass through; when closed, the ball rotates to block the flow.

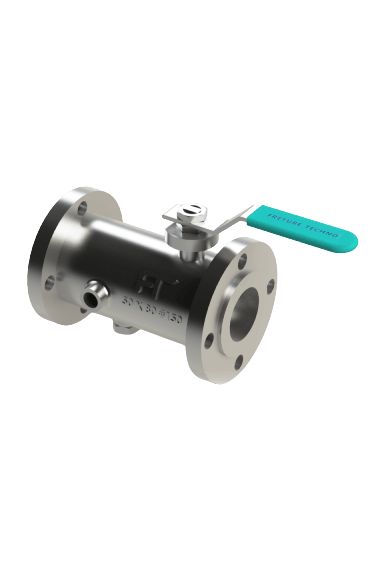

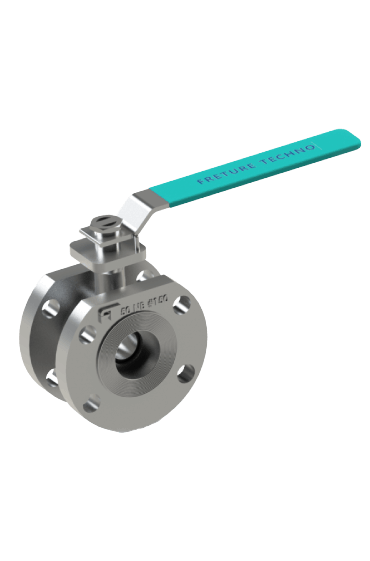

Forged Ball Valve

Forged Ball Valve, as the name suggests, is made using the method of forging.

Freture Techno Pvt. Ltd is a leading forged ball valve manufacturer, supplier, and exporter from Mumbai, India. We offer a wide range of high-quality forged ball valves in a variety of sizes, materials, and finishes. Our forged ball valves are made to the highest standards and are backed by our comprehensive warranty.

Forged Ball valves are easy to make in any shape and size that you want. Forged Valves usually have a thinner wall than most other types of valves. This type of valve is ideal for machines that work at extreme temperatures since they have the ability to heat up or cool down very quickly.

What are Forged Ball Valves?

A forged ball valve is a type of valve that uses a ball with a hole through the center to control the flow of fluid. The ball is rotated to open or close the valve. We are Forged ball valves suppliers in India. Forged Ball Valves are made from a single piece of metal, which makes them strong and durable. They are also resistant to corrosion, making them ideal for use in harsh environments.

How Forged Ball Valves Work?

When the ball is in the open position, the hole in the ball allows fluid to flow through the valve. When the ball is in the closed position, the hole is blocked, preventing fluid from flowing through the valve.

Features of Forged Ball Valves

- Strong and durable

- Resistant to corrosion

- Easy to operate

- Wide range of sizes and materials available

- Applications of Forged Ball Valves

Forged ball valves are used in a variety of applications, including:

- Oil and gas

- Chemical processing

- Water treatment

- Power generation

- HVAC

- Food and beverage

Benefits of Using Forged Ball Valves

There are many benefits to using forged ball valves, including:

- Strength and durability: Forged ball valves are made from a single piece of metal, which makes them strong and durable. They can withstand high pressures and temperatures, making them ideal for use in demanding applications.

- Corrosion resistance: Forged ball valves are resistant to corrosion, making them ideal for use in harsh environments. This is because the forging process creates a dense, uniform metal structure that is less likely to be damaged by corrosive elements.

- Easy operation: Forged ball valves are easy to operate. They can be opened and closed quickly and easily, even under pressure. This makes them ideal for use in applications where rapid shut-off is required.

- Wide range of sizes and materials: Forged ball valves are available in a wide range of sizes and materials. This allows you to choose the right valve for your specific application

If you are looking for a high-quality, durable, and reliable forged ball valve, then Freture Techno Pvt. Ltd is the perfect choice for you. Contact us today to learn more about our forged ball valves and how we can help you meet your needs.

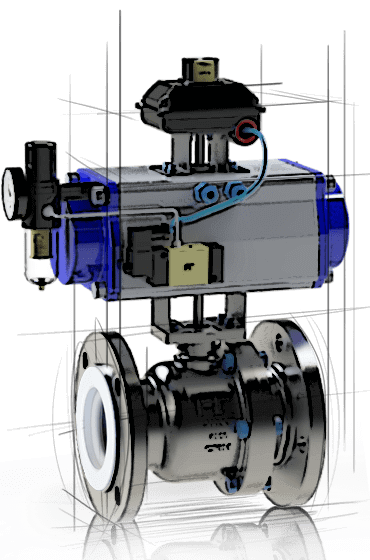

Description | Features |

|---|---|

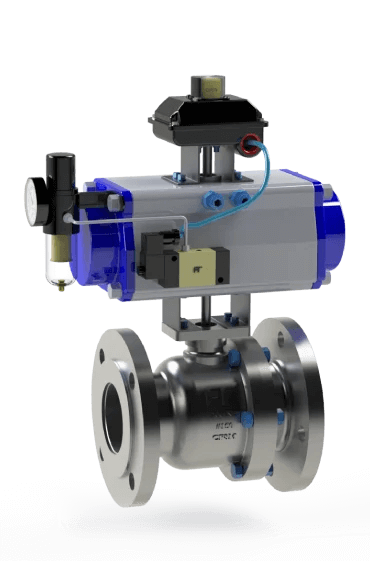

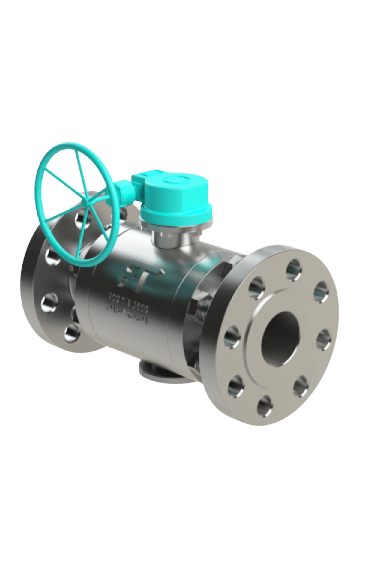

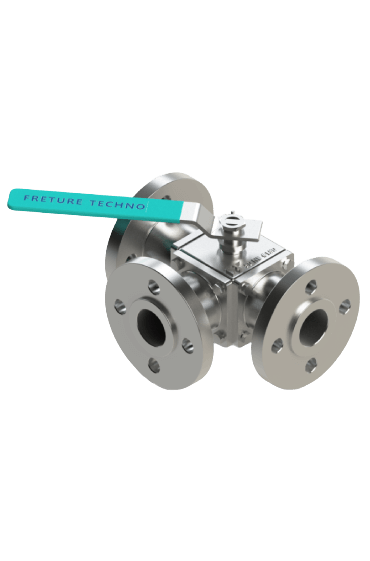

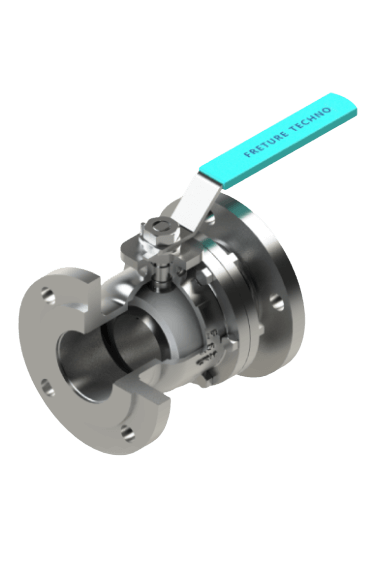

TYPE: Forged Two piece / Three Piece Size: 15 NB - 300 NB End Connection: Socket Weld / Screwed End Class: 150# - 2500# Temperature Range: 7Deg C to 280 Deg C Body Materials: Stainless Steel / Carbon Steel / Alloys Design Standard:API 6D / ISO 17292 rev 2004 / BS 5351 End Connection Std.: ASME B16.11 / ANSI 1.20.1 Operation: Manual & Actuated (Rack & Pinion / Scotch Yoke / Electric) Gear Operated Face to Face: ANSI B16.10 Testing: API 598 Rev 2009 Sour Service: NACE MOR 0175 Rev 2009 Documents: BS/EN 10204-3.1 REV 2004 |

|

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is Forged Ball Valve ?

- How does it work?

Forged Ball Valves operate by using a spherical ball with a hole through the middle to control the flow of fluid. When the handle is turned, the ball rotates to open or close the valve.

- What are the main applications?

Forged Ball Valves are commonly used in various industries such as oil and gas, petrochemical, chemical, power generation, and water treatment for fluid regulation and shut-off.

- What are the benefits of using one?

The benefits of using Forged Ball Valves include excellent sealing performance, high-pressure and high-temperature capabilities, minimal pressure drop, and enhanced durability and reliability.

- What materials are used in their construction?

Forged Ball Valves are typically constructed from materials such as stainless steel, carbon steel, alloy steel, and other high-strength materials to withstand harsh operating conditions.

- How do I choose the right one for my application?

When selecting a Forged Ball Valve, consider factors such as pressure rating, temperature range, fluid type, valve size, end connections, and environmental conditions to ensure compatibility with your specific application requirements.

- Can they be repaired?

Yes, Forged Ball Valves can be repaired. Common repairs may include replacing worn seals, bearings, or other components to restore the valve's functionality.

- What maintenance is required?

Regular maintenance of Forged Ball Valves typically includes inspection, lubrication of moving parts, and replacement of worn or damaged components as needed to ensure optimal performance and reliability.

- Are they available in different designs?

Yes, Forged Ball Valves are available in various designs, including floating ball, trunnion mounted ball, and top entry ball valves, to suit different applications and operating conditions.

- Why is Freture the best place to buy from?

Freture is the preferred choice for purchasing Forged Ball Valves due to our commitment to quality, precision engineering, extensive industry experience, and dedication to customer satisfaction. We offer a wide range of high-quality valves, expert technical support, and competitive pricing, ensuring that our customers receive reliable solutions tailored to their needs.

Industries where Forged Ball Valve is Used

Oil and Gas Industry

Petrochemical Industry

Chemical Processing

Power Generation

Pulp and Paper Industry

Applications of Forged Ball Valve

- Isolation: They are used for isolating sections of pipelines to stop or regulate the flow of fluids.

- On/Off Control: They provide efficient on/off control in various industrial processes.

- High-Pressure Applications: They are ideal for high-pressure applications due to their robust construction and sealing capabilities.

- Corrosive Fluid Handling: They are suitable for handling corrosive fluids in industries such as chemical processing and petrochemicals.

- Versatile Fluid Compatibility: They can handle a wide range of fluids, including liquids, gases, and slurries.

- Emergency Shut-off: They are commonly used for emergency shut-off applications in critical systems to prevent accidents or spills.