Double Block & Bleed Valves are one of the safest and most efficient valves available. The fact that highly sensitive industries like oil and gas and chemical manufacturing companies use it extensively is proof that it is 100% safe and reliable.

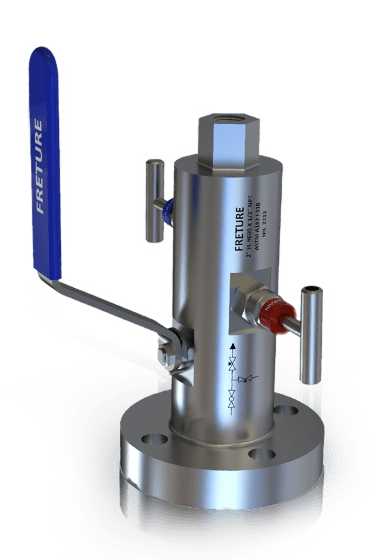

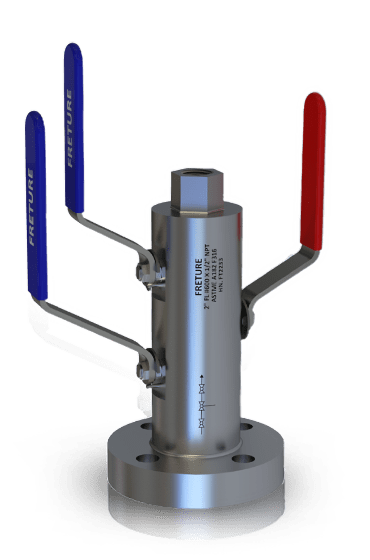

Double Block And Bleed Valve

Elevate safety and efficiency with the Double Block & Bleed Valve, engineered for uncompromising performance.

We are a leading Double Block and Bleed Valves (DBB) manufacturer in Mumbai, India, with multifaceted roles, and versatility across diverse applications. Whether for general utility or as a pivotal component in fuel service systems, these valves provide paramount control over fluid flow. With our unique design featuring dual isolation and bleed capabilities, they ensure heightened safety and efficiency, surpassing standard instrumentation ball valves. From regulating flow in industrial processes to safeguarding critical systems, DBB Valves from Feature stand as the superior choice, empowering seamless operations and peace of mind.

Description | Features |

|---|---|

TYPE: Ball Valve / Globe Type, Needle Ball-Needle-Ball Type End Connection: Flange / Butt Weld Size: 8NB - 100NB Pressure Rating: #150 - #2500 Temperature Range: -7Deg C to 280 Deg C Body Materials: Stainless Steel / Carbon Steel / Alloys Design Standard: MESC SPE 77-170, MESC SPE 77-130, MESC SPE 77 and ASME B16.34 Face to Face: ASME B16.10 Rev 2009 Safety: NACE MOR 0175 , BS/EN 10204-3.1 REV 2004, API 598 Rev 2009, API-607 |

|

Related Products

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- Are Double Block & Bleed Valves safe?

- Do I really need a Double Block & Bleed Valves for my factory?

If you are in one of the following industries, a Double Block & Bleed Valves will definitely help you improve the efficiency and safety.

- Chemical Manufacturing

- Oil & Gas Refineries

- Boiler / Reactor Manufacturing

- EPC Contractor company

- Local Traders

If you’re from another industry looking for more details about how you can benefit from using a Instrumentation Ball Valve, please get in touch with us here for further discussion.;

- How does it work?

A Double Block and Bleed (DBB) valve isolates a section of piping by using two seating surfaces to create a double barrier against flow, with a bleed valve in between to depressurize or vent the cavity.

- What are the main applications?

DBB valves are used in oil and gas, petrochemical, chemical processing, power generation, and water treatment industries for isolating sections of pipelines, preventing contamination, and ensuring system integrity during maintenance.

- What are the benefits of using one?

Benefits include enhanced safety, reliable isolation, leak detection, reduced downtime during maintenance, and compliance with regulatory standards.

- What materials are used in their construction?

Common materials include stainless steel, carbon steel, alloy steel, and special alloys to withstand high pressures, temperatures, and corrosive environments.

- How do I choose the right one for my application?

Consider factors such as pressure and temperature ratings, material compatibility with the fluid, valve size, end connections, and specific application requirements.

- Can they be repaired?

Yes, DBB valves can be repaired, with replacement parts available for seats, seals, and other components, ensuring long-term operational reliability.

- Why is Freture the best place to buy DBB Valves from?

- High Quality: Meets API and ASME standards.

- Custom Solutions: Tailored to specific needs.

- Expertise: Experienced manufacturing team.

- Great Support: Excellent customer service.

- Innovative Design: Advanced, durable valves.

Industries where Double Block & Bleed Valves (DBB valves ) is used

Oil & Gas Industry

Chemical Processing

Power Generation

Water Treatment

Pulp & Paper Industry

Applications of Double Block & Bleed Valves

- Isolation in Piping Systems: This ensures complete isolation of a section of piping for maintenance and safety.

- Pressure Relief: Used to safely relieve pressure in pipelines during maintenance or emergency shutdowns.

- Flow Control: Provides precise control and regulation of fluid flow in critical applications.

- Leak Detection: Enables detection of leaks in high-pressure systems by bleeding off pressure between two seals.

- Instrument Calibration: Used for safe calibration and testing of instruments in pressurized systems.