While both use a rotating disc for flow control, the valve is generally used for controlling air or gas flow in HVAC or industrial exhaust systems, while a Butterfly valve is typically used in pipelines to control the flow of liquids or gases.

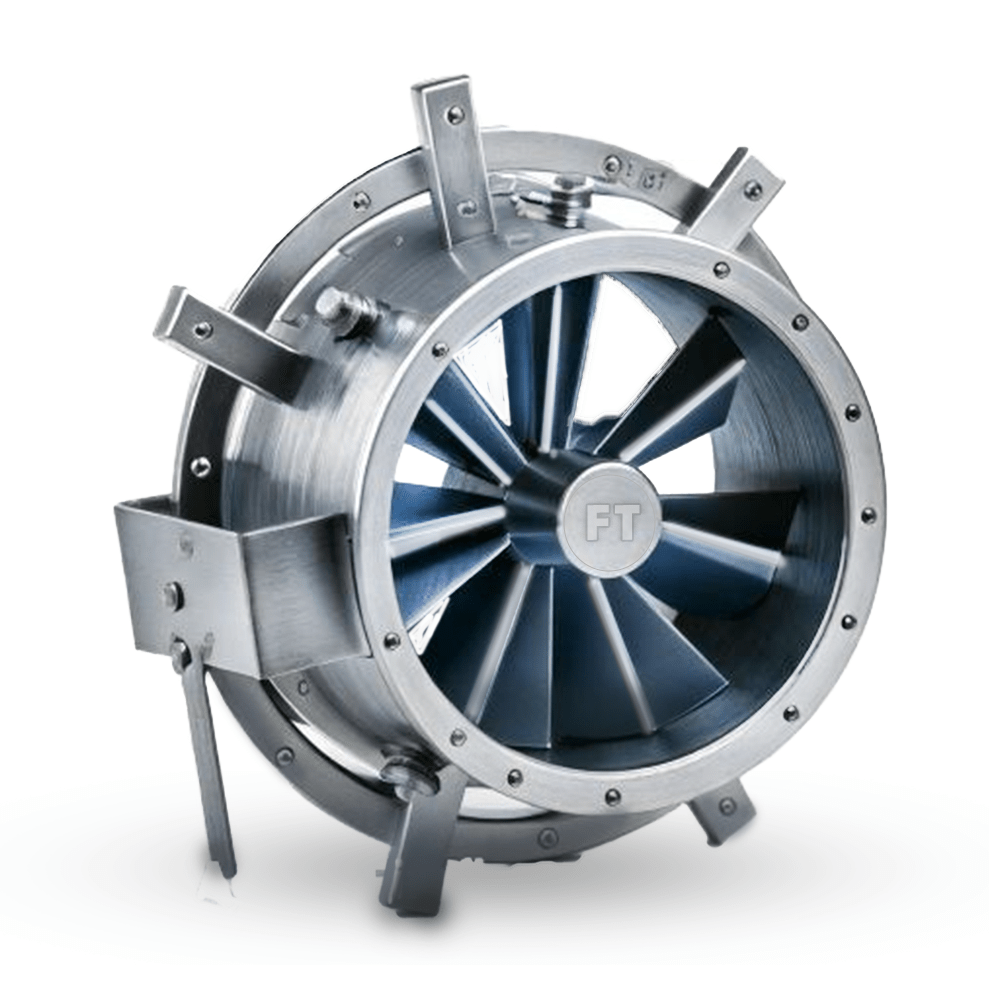

Butterfly Damper

Swift, reliable airflow control with a compact, versatile design.

Freture Techno is a leading Butterfly Damper valves manufacturer in Mumbai, India, recognized for delivering high-quality, reliable solutions for industrial flow control. They play an essential role in managing airflow and pressure in various industrial applications. With precision engineering, advanced materials, and a focus on efficiency, They are trusted across sectors requiring dependable, effective control of air and gas flow.

What Is a Butterfly Damper Valve?

It is a type of control device used to regulate the flow of gases and air within ventilation and exhaust systems. The design features a rotating disc or vane mounted on a central axis within a circular duct, which can be turned to modulate or block airflow as needed. By adjusting the position of the disc, airflow is controlled with precision, making these dampers ideal for systems that require flexibility and efficiency. Available in both manual and motorized versions, They offer simple operation and long-term reliability in demanding environments. They are widely utilized in baghouses, balancing systems, combustion air control systems, incinerators, scrubber units, and for stack isolation.

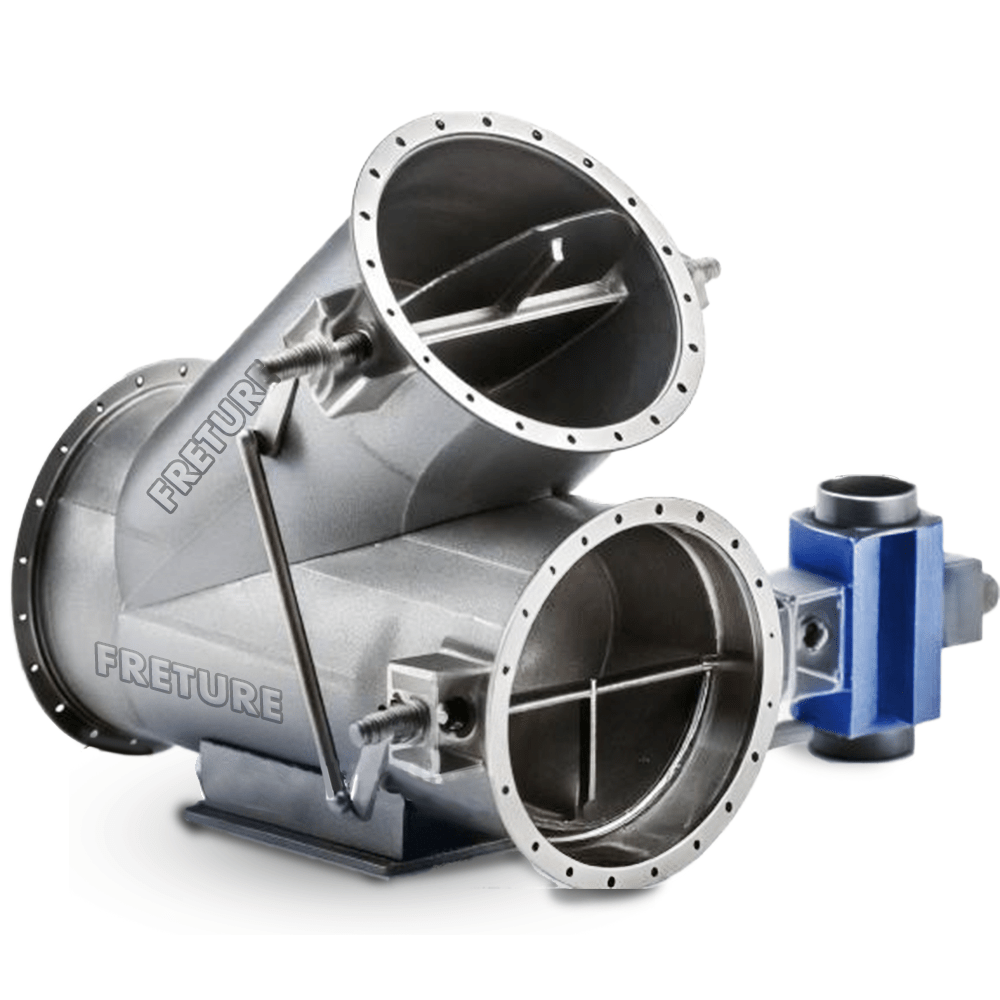

Butterfly Damper Types

It suits diverse industrial requirements. Each type is designed with a specific function in mind to meet the unique demands of various systems:

Motorised: Equipped with electric or pneumatic actuators, these dampers offer automated control of airflow, which is essential for operations needing precise modulation and remote control capabilities.

Manual: Designed for simpler applications, manual dampers allow users to adjust airflow by hand. These are ideal for setups where frequent adjustments are unnecessary or where power isn’t available.

MS (Mild Steel) and SS (Stainless Steel): Made from mild steel or stainless steel, these dampers cater to different levels of durability and environmental resistance. Stainless steel dampers are highly resistant to corrosion, making them suitable for humid or corrosive environments. Each of these options provides unique advantages, ensuring that Butterfly Damper Valves deliver optimal performance under a variety of industrial conditions.

Why Choose Freture Techno?

Freture Techno emphasises quality, precision, and customer satisfaction. Each product is meticulously crafted to meet high standards of performance and durability. With a commitment to excellence and a customer-focused approach, We are engineered to deliver lasting performance in demanding industrial applications.

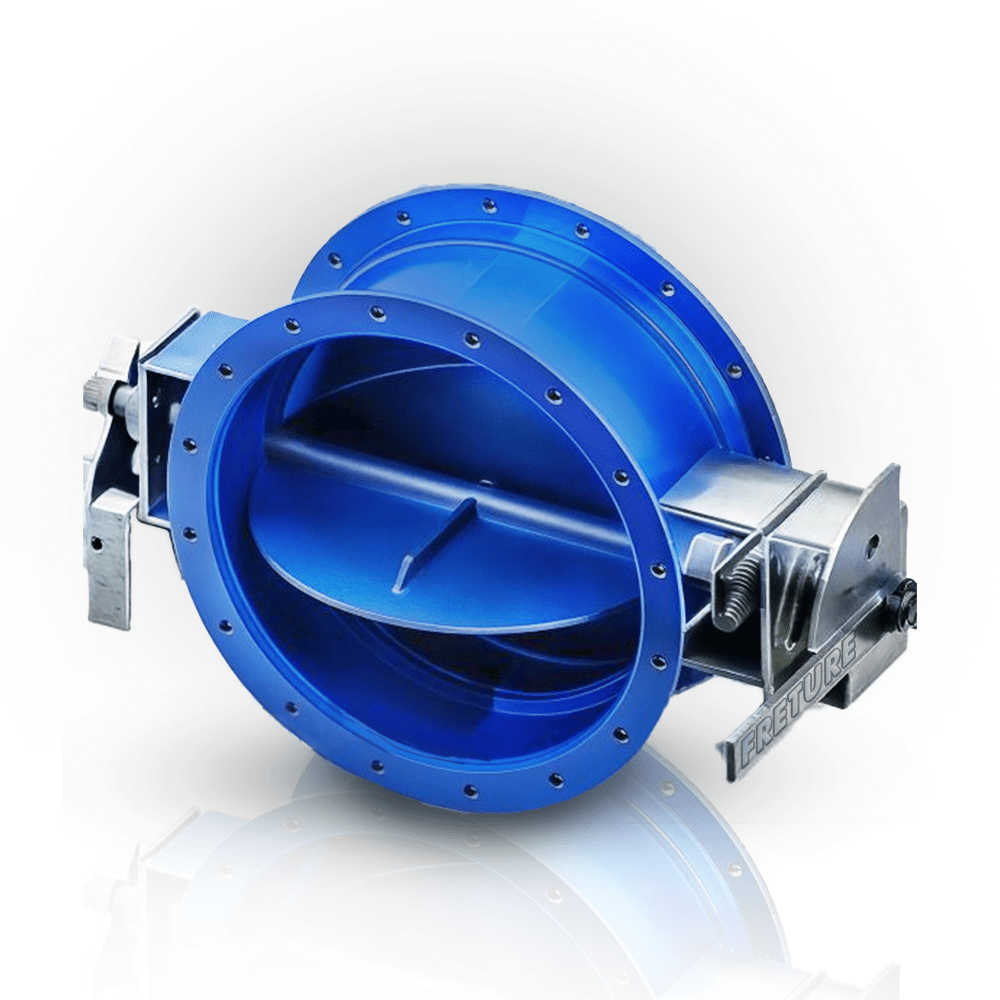

Specifications | Features |

|---|---|

Type: Butterfly Sizes: 6" to 144" Process Temperature: Up to 200˚F Configurations: Round, Square, Rectangular Construction: Stainless Steel, Carbon Steel (Other materials available) Shutoff: Up to 99% Seal Options: Tadpole, Metal Seat, Swing-Thru Actuation: Manual, Electric, Pneumatic (Failsafe available) Modulation: Open/Closed or Modulating Pressure Rating: Up to 1 PSI & 4000 FPM process air (Higher available) Bearings: Ball Bearings & Shaft Packing Glands Standard High-Temp Bearings: Carbon Sleeve Bearings (Standard over 400˚F)

|

|

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- How does Butterfly Damper Valve differ from a standard Butterfly Valve?

- What are the main applications for these valves?

They are commonly used in HVAC systems, industrial ventilation, dust collection, exhaust systems, and environmental control systems, where precise airflow regulation is needed.

- What materials are used to make these valves?

These valves are usually made from materials like stainless steel, mild steel, or other corrosion-resistant alloys, depending on the operating environment and the nature of the gases or air they control.

- Are these valves suitable for high-temperature environments?

Yes, certain they are designed with heat-resistant materials or coatings, making them suitable for high-temperature applications in exhaust or combustion systems

- What types of actuators are used with these valves?

The valves can be operated manually, or equipped with pneumatic, electric, or hydraulic actuators for automated control. The choice of actuator depends on the level of control required and the system design.

- How do motorised valves work?

Motorised Butterfly Damper valves use an electric motor to control the rotation of the valve disc, allowing for precise and automated flow adjustment, which is ideal for remote or complex control systems.

- What is the purpose of a Pneumatic Butterfly Damper valve?

The valve uses air pressure to operate the disc, providing reliable, fast actuation. These are often used in industrial applications where rapid or frequent adjustment is required.

- How do I select the right size for these valves?

The correct size is determined by the system's duct diameter, flow requirements, and pressure conditions. Consulting with a manufacturer or technical expert can help ensure accurate sizing.

- What maintenance is needed for these valves?

Regular maintenance includes inspecting the valve disc, seals, and actuator for wear or damage, ensuring the valve is properly lubricated, and periodically testing for consistent operation to maintain optimal performance and longevity.

Industries where this is Used

Power Generation

HVAC Industry

Oil and Gas Industry

Wastewater Treatment

Petrochemical Industry

Applications

- Cooling Tower Airflow Management – Controls airflow to optimize cooling efficiency.

- Selective Catalytic Reduction (SCR) Systems – Controls NOx emissions in power plants.

- Carbon Capture & Storage (CCS) – Helps control flue gas in CO₂ capture processes.

- Pipeline Pressure Regulation – Maintains stable pressure in gas pipelines.

- Air Pollution Control – Directs exhaust gases through scrubbers or filters.

- Corrosive Gas Handling – Handles aggressive chemical vapors safely.

- Variable Air Volume (VAV) Systems – Ensures dynamic air distribution for efficiency.