They are primarily used to control and direct the flow of gases, especially in industrial processes involving turbines, boilers, and ducts.

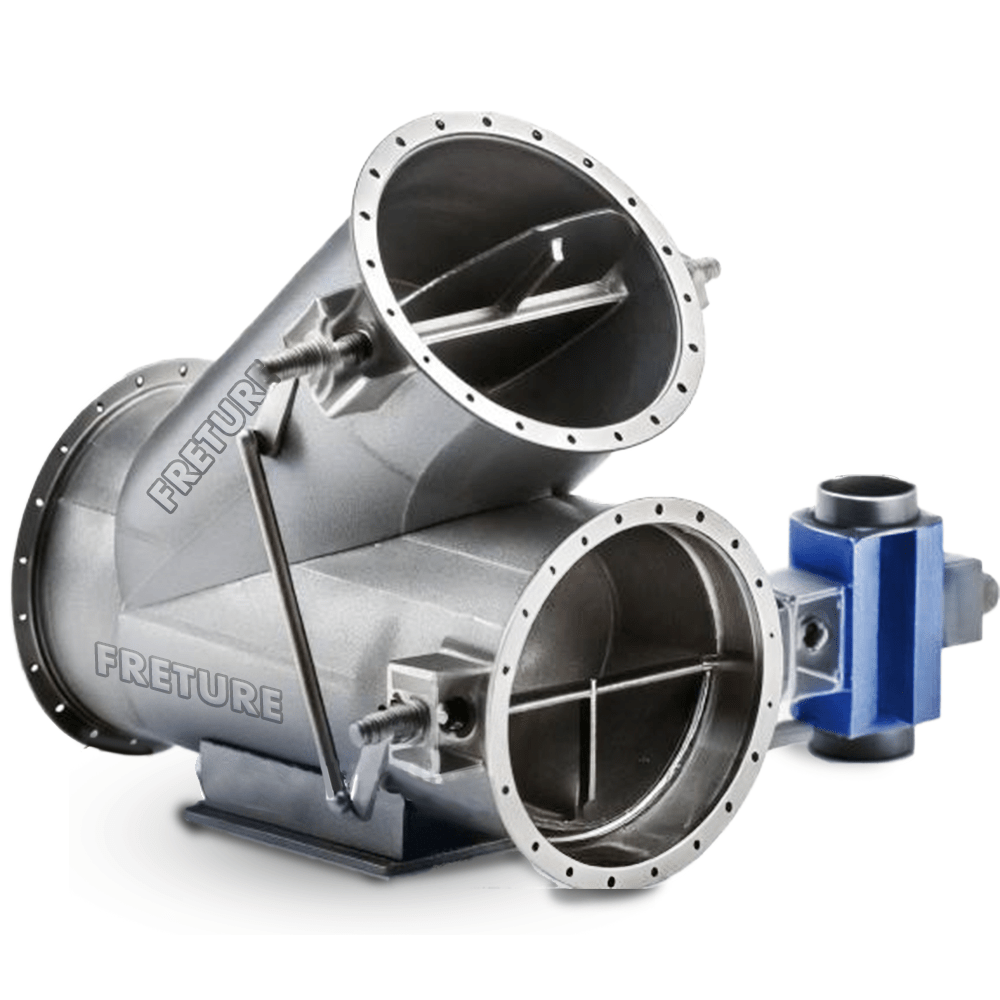

Y Diverter Damper

flexible airflow redirection for enhanced system control

Freture Techno is a leading Diverter Damper manufacturer in Mumbai, India, also specializing in high-quality Diverter Dampers. Y Diverter Dampers are specialized devices used to control and redirect airflow within duct systems. Shaped like the letter "Y," they split or merge air streams to channel flow into different pathways. This design enables precise control over air distribution, optimizing system efficiency, reducing energy loss, and ensuring that each area receives the appropriate amount of conditioned air. Known for precise airflow control and reliability under demanding conditions, They are essential components in industrial applications, particularly where efficient gas or air flow control is critical.

Specifications | Features |

|---|---|

Type: Single Louver, Multi-Louver, Flap, Tee Diverter Damper Sizes: 10" to 46" Process Temperature: Up to 1800˚F Configurations: Round, Square, Rectangular Angles Available: 90° & 45° (Others on request) Construction: Stainless Steel, Carbon Steel (Other materials available) Shutoff: Up to 99% Seal Options: Tadpole, Metal Seat, Swing-Thru Actuation: Manual, Electric, Pneumatic (Failsafe available) Modulation: Open/Closed or Modulating Pressure Rating: Up to 1 PSI & 4000 FPM process air (Higher available) Bearings: Ball Bearings & Shaft Packing Glands Standard High-Temp Bearings: Carbon Sleeve Bearings (Standard over 400˚F) |

|

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is a Diverter Damper used for?

- Can these Dampers handle high temperatures?

Yes, they are designed for high-temperature applications, with models capable of handling temperatures up to 1000°C.

- Are these Dampers available in different sizes?

Yes, sizes range from DN 100 to DN 2500, and custom sizes can be manufactured as per specific requirements.

- What end connections are available for these dampers?

Options include flanged and welded connections, customizable to suit various industrial needs.

- What materials are used in construction?

They are manufactured using Carbon Steel, Stainless Steel, Alloy Steel, and refractory-lined options for enhanced durability.

- Are these dampers fire-safe?

Yes, it incorporates a fire-safe design for safe operation in high-temperature environments

- What types of operations are supported?

We offer Motorized, Pneumatic, Hydraulic, and Manual options for operational flexibility.

- How long is the cycle life of these Damper?

These dampers are built for a long cycle life, ensuring durability and performance with minimal maintenance.

- Are there any documents provided with the product?

Yes, we provide MTR, Material & Performance Test Certificates, and dimensional drawings.

- Do you offer customized designs for specific applications?

Yes, our team can design and manufacture custom Dampers tailored to your unique operational requirements.

Industries where Diverter Damper is used

Power Generation

Oil and Gas Industry

Chemical Processing

Pharmaceutical Industry

Food & Beverage Industry

Applications of Diverter Damper

- Bypass Air Management – Adjusts airflow when certain sections require less cooling or heating.

- Variable Air Volume (VAV) Systems – Modulates air distribution to maintain comfort and efficiency.

- HVAC Load Balancing – Adjusts air distribution based on server heat output.

- Laminar Flow Systems – Directs clean air in controlled environments.

- Airborne Contaminant Control – Prevents cross-contamination by managing airflow.

- Demand-Controlled Ventilation (DCV) – Adjusts air intake based on occupancy and air quality sensors.