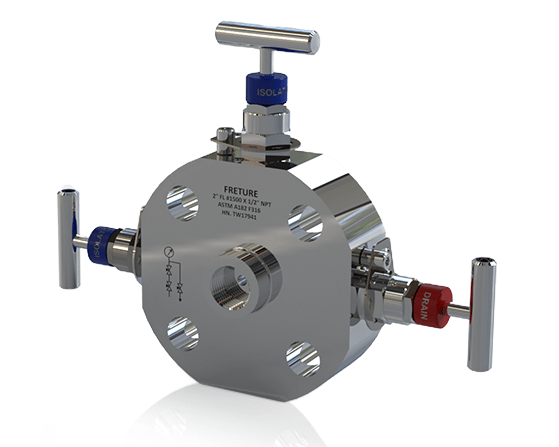

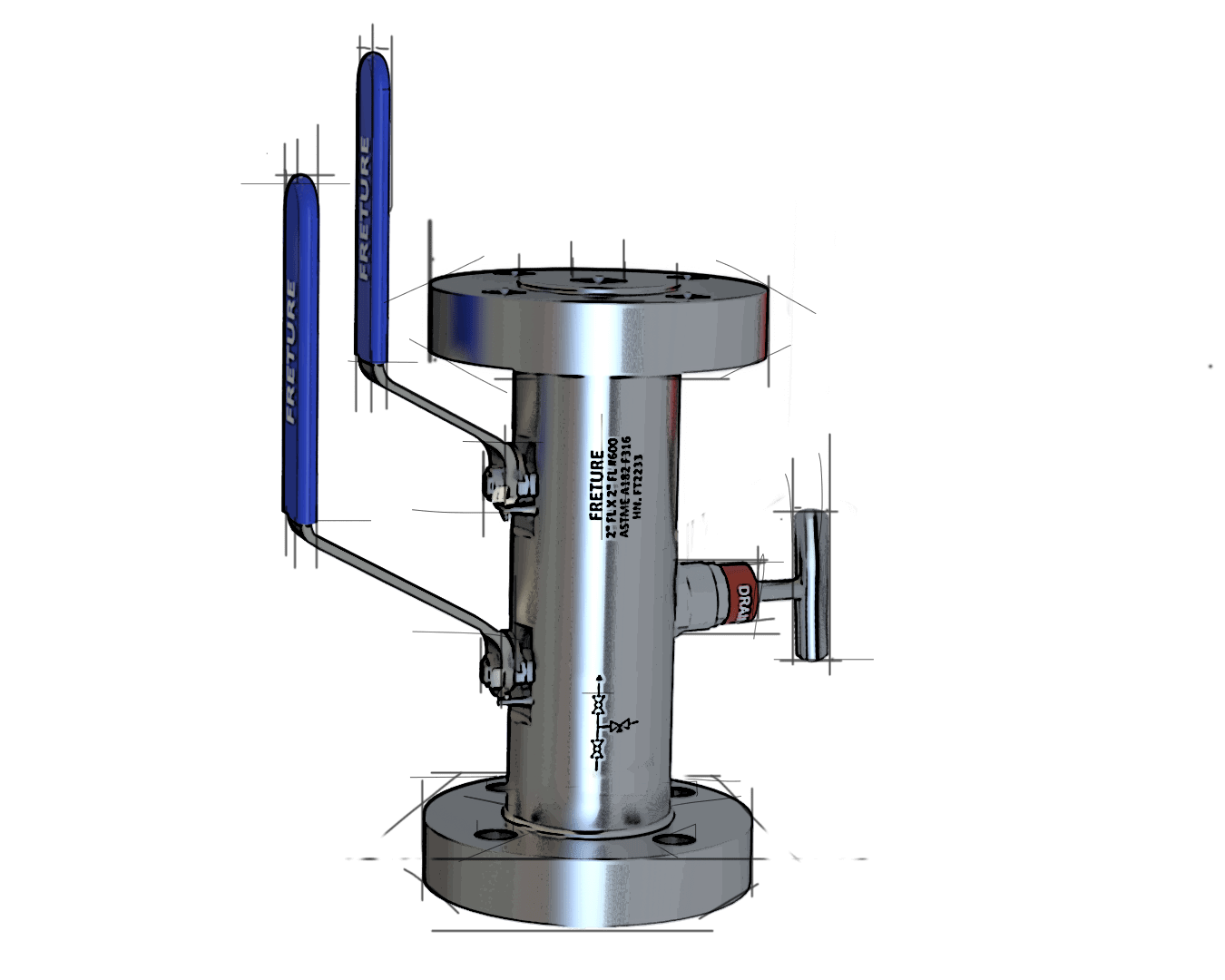

A monoflange valve is a compact instrumentation valve that integrates one, two, or three needle valves into a single flange body, reducing piping complexity and leak points.

Monoflange Valve

Redefining Excellence in Monoflange Valve Innovation

We are leading Monoflange Valve manufacturer in Mumbai, India, We meticulously craft our products to the highest manufacturing standards. Monoflange Valve epitomizes precision, reliability, and versatility. Designed to streamline installation and reduce potential leak points, it serves as a compact, all-in-one solution for instrumentation and gauge applications.

With its robust construction and adherence to stringent quality control measures, our Monoflange Double Block and Bleed stands as the preferred choice across various industries, ensuring seamless performance and unparalleled safety in critical environments. Trust Feature Techno for unparalleled expertise in Monoflange Valve technology, empowering your operations with unmatched efficiency and confidence.

Key Features

Compact Integrated Design

Combines multiple needle valves in one flange body, minimizing piping connections and potential leakage points.High Safety Performance

Reduced joints ensure improved sealing integrity, making monoflange valves ideal for high-pressure and hazardous process environments.Space and Weight Optimization

Perfect for offshore platforms, skid-mounted systems, and tight instrumentation layouts.Precision Flow Control

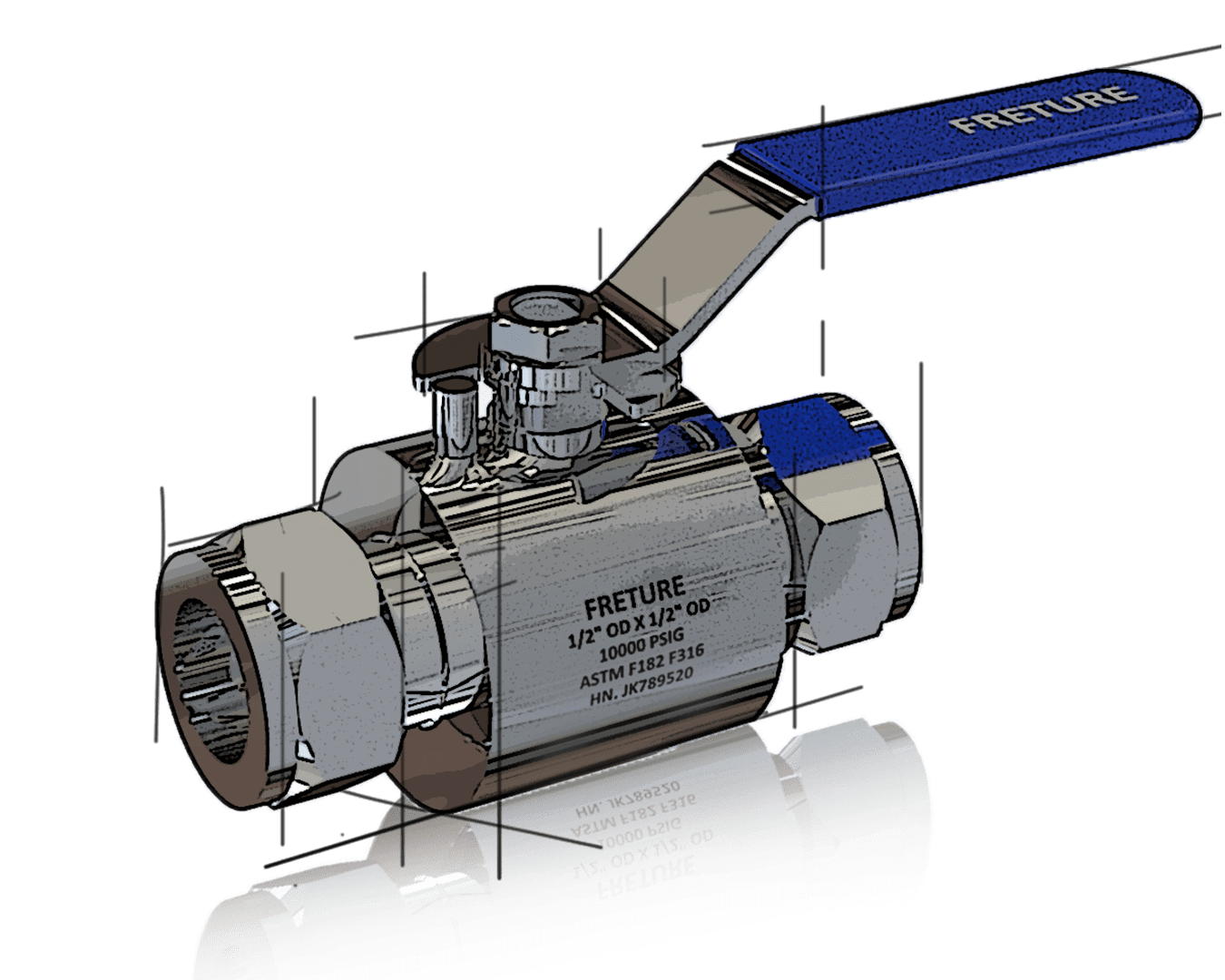

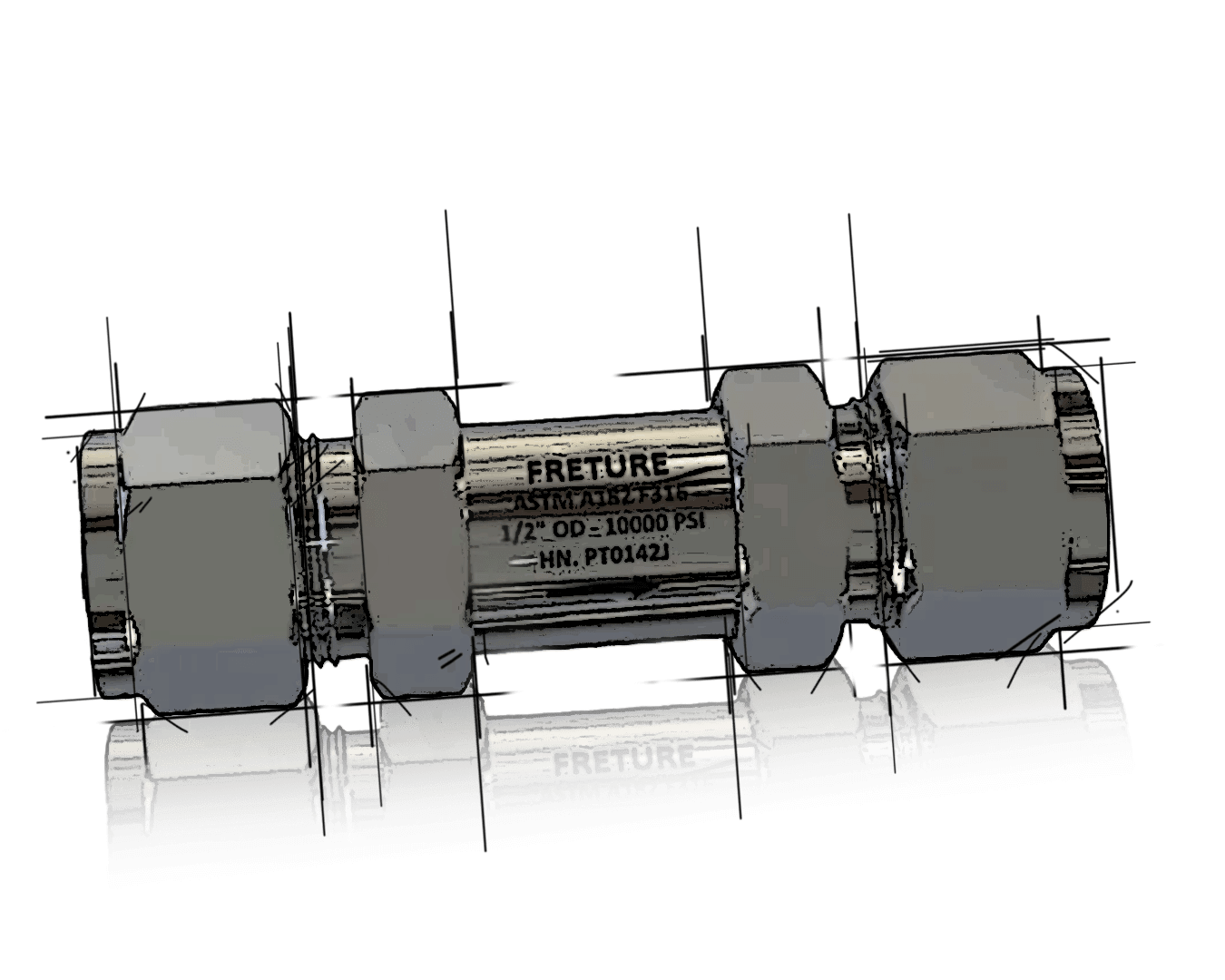

Needle valve construction allows accurate isolation and venting for pressure instruments.Robust Construction

Manufactured from forged materials to withstand high pressure and temperature conditions.

Types of Monoflange Valves

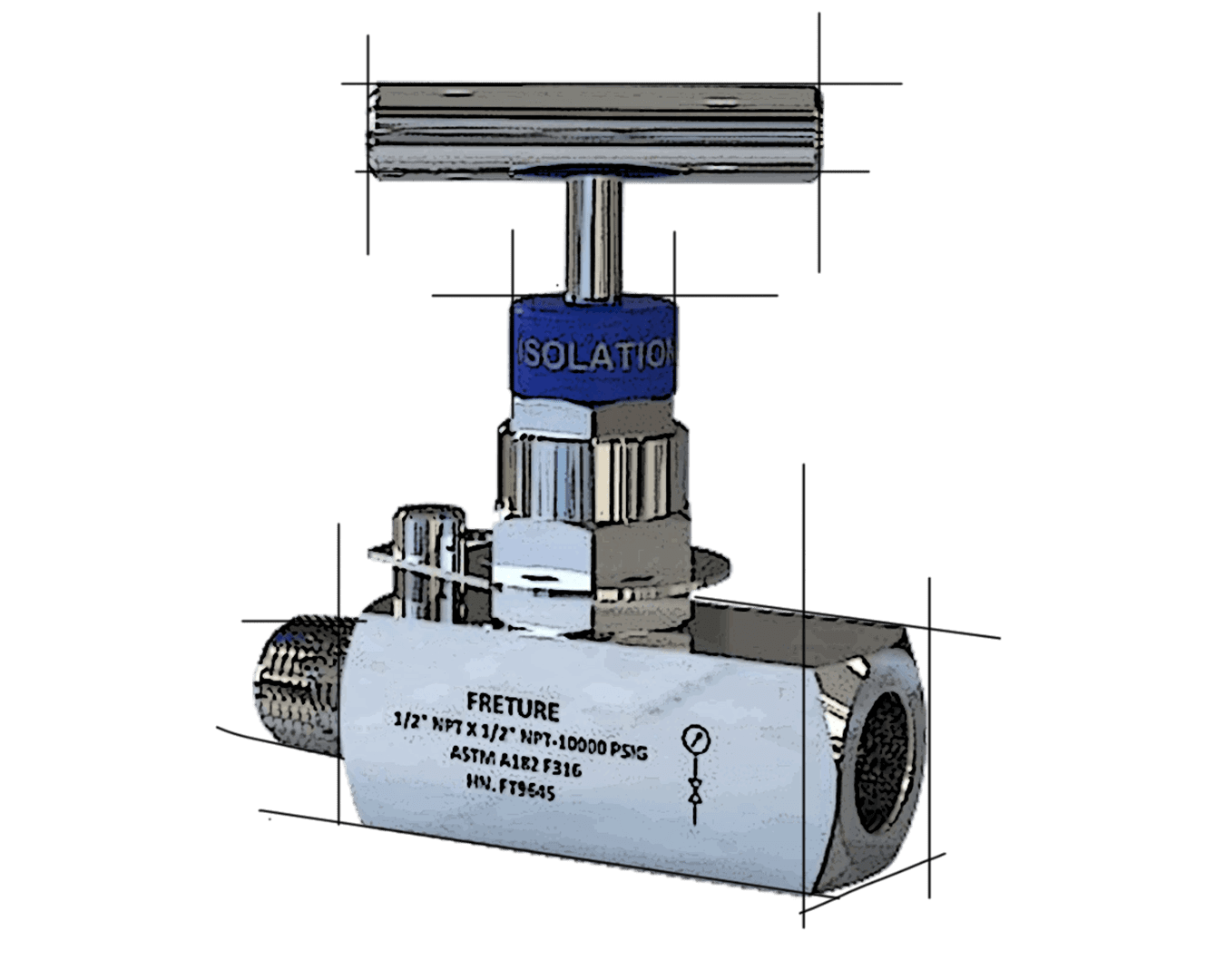

Single Monoflange Valve – One needle valve for basic isolation

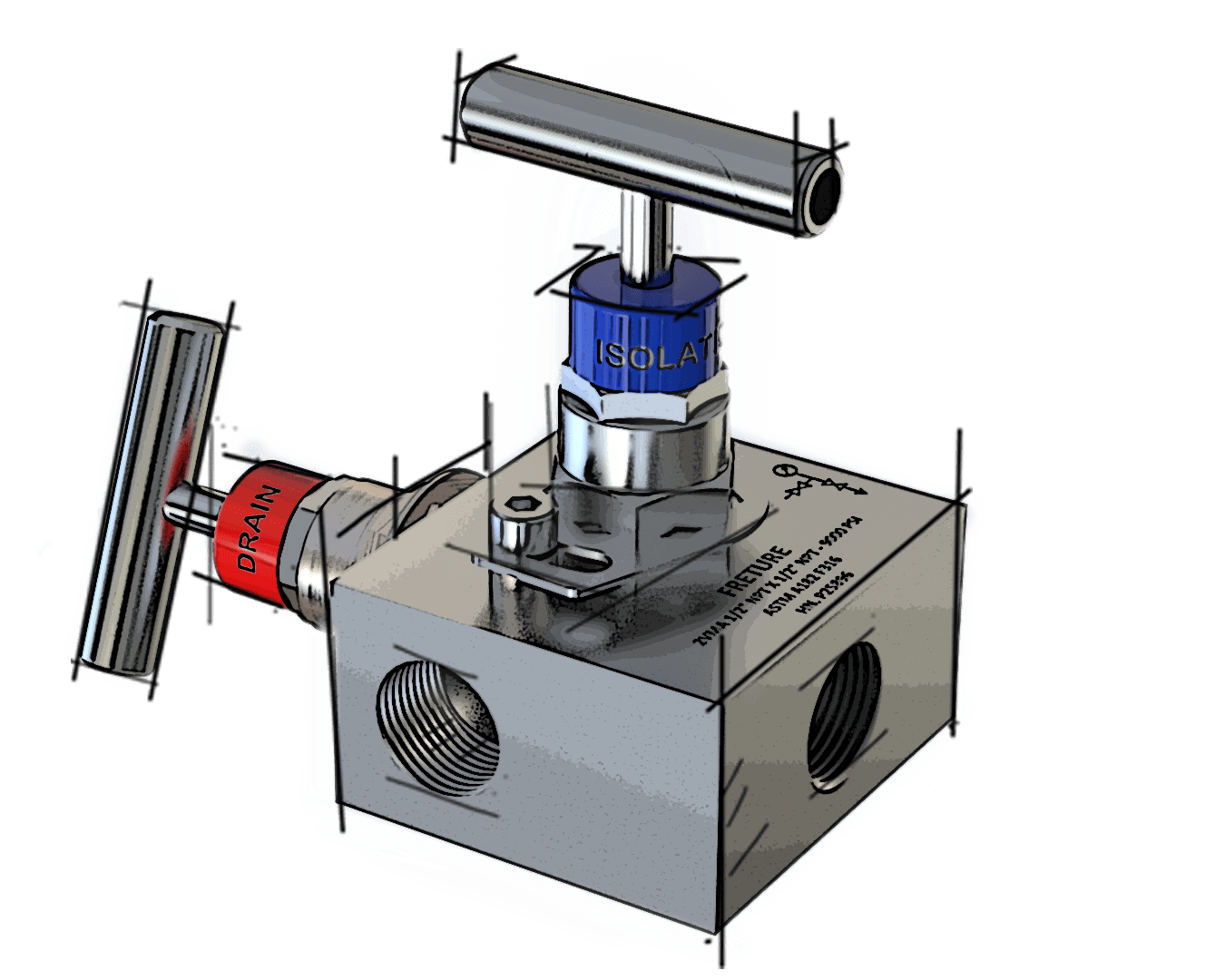

Double Monoflange Valve – Two needle valves for isolation and venting

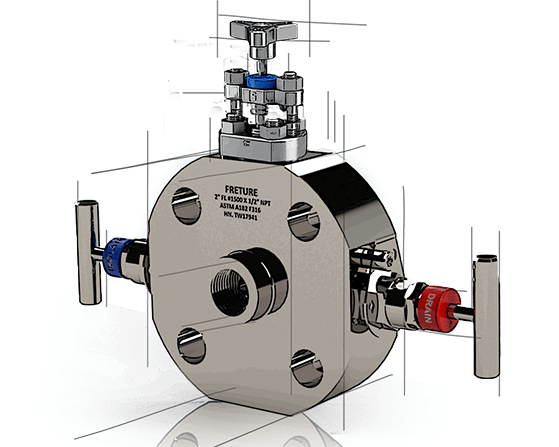

Triple Monoflange Valve – Three needle valves for isolation, equalization, and venting

These configurations make monoflange valves suitable for various pressure transmitter installations.

Advantages Over Conventional Valve Manifolds

Monoflange valves offer a superior alternative to traditional valve manifolds by reducing installation complexity, improving system safety, and lowering maintenance requirements. Their compact design enhances operational efficiency while maintaining high reliability in demanding industrial environments.

Why Choose Monoflange Valves

Selecting a high-quality monoflange valve ensures long-term performance, reduced downtime, and enhanced process safety. Precision engineering, robust materials, and compliance with industry standards make monoflange valves a dependable solution for critical instrumentation applications.

A Monoflange Valve is an essential instrumentation component that delivers compactness, safety, and operational efficiency. Designed for high-pressure applications, it simplifies piping layouts while ensuring reliable isolation and control. For industries seeking a durable and space-efficient instrumentation valve solution, monoflange valves remain the preferred choice.

Description | Features |

|---|---|

TYPE: Single Monoflange Valve, Double Monoflange Valve, Triple Monoflange Valve End Connection: Flange / Threaded Size: 8 NB - 100 NB Class: 150# - 2500# Temperature Range: -7 °C to 280 °C Body Materials: Stainless Steel / Carbon Steel / Alloys Design Standard: MESC SPE 77-170 / 130 / 165 / ASME B 16.34 Face to Face: ASME B16.10 Rev 2009 Fire safe design: API-607 Rev 2010 Testing: API 598 Rev 2009 Sour Service: NACE MR0175 Rev 2009 Safety: NACE MOR 0175 , BS/EN 10204-3.1 REV 2004, API 598 Rev 2009, API-607 |

|

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is a Monoflange Valve?

- How Does It Work?

A monoflange works by providing multiple valve functionalities within a single assembly. It allows for isolation of process fluids, venting of pressure, and draining of fluids, all within one compact and integrated design. This simplifies installation and reduces potential leak points.

- What Are the Main Applications?

Monoflanges are mainly used in the oil and gas, petrochemical, and chemical industries. They are ideal for use in instrumentation systems, sampling systems, and in applications requiring compact valve arrangements for process isolation and control.

- What Are the Benefits of Using One?

- Space and Weight Savings: Combines multiple valves into one compact unit, reducing installation space and weight.

- Reduced Leak Paths: Fewer connections minimize the potential for leaks.

- Simplified Installation: Streamlines installation with fewer components and connections.

- Improved Safety: Provides reliable isolation and pressure relief functions in a single device.

- What Materials Are Used in Their Construction?

Stainless Steel (316, 316L) ,Carbon Steel, Alloy Steel (Monel, Hastelloy), Duplex and Super Duplex Stainless Steel Other materials may be available based on specific application requirements.

- How Do I Choose the Right One for My Application?

To choose the right monoflange, consider:

- Process Conditions: Pressure, temperature, and type of fluid.

- Material Compatibility: Ensure materials are compatible with the process fluid.

- Connection Type: Match the end connections (flanged, threaded, welded) with your system.

- Standards and Certifications: Compliance with industry standards (e.g., API, ASME).

- Can They Be Repaired?

Monoflanges can often be repaired depending on the design and the nature of the damage. Consult the manufacturer for specific repair instructions and available repair kits.

- What Maintenance Is Required?

Regular maintenance includes:

- Periodic inspection for leaks and wear.

- Routine operation to ensure valve functionality.

- Cleaning and lubrication as needed.

- Following manufacturer’s maintenance guidelines.

- Are They Available in Different Designs?

Yes, monoflanges are available in various designs to suit different applications, including different valve configurations, end connections, and materials.

- Why Is Freture the Best Place to Buy From?

Freture is the best place to buy monoflanges because of:

- High-Quality Products: Manufactured to strict standards ensuring reliability and performance.

- Wide Range of Options: Extensive selection of materials, sizes, and configurations.

- Expert Support: knowledgeable staff to help you select the right product for your application.

- Competitive Pricing: Offering value without compromising on quality.

- Excellent Customer Service: Committed to customer satisfaction and support.

Choosing Freture ensures you get a high-quality, reliable monoflange tailored to your specific needs.

Industries where Monoflange Valve is used

Chemical Processing

Oil & Gas Refineries

Power Generation

Food & Beverage Industry

Water Treatment Plant

Applications of Monoflange Valve

- Instrumentation: Monoflanges are ideal for mounting pressure gauges, transmitters, and other instruments. Their compact design eliminates multiple fittings and reduces potential leak points, saving space.

- Process Isolation: They are used to isolate instruments from the process fluid for maintenance or calibration. The block and bleed functionality allows venting any trapped pressure before removing the instrument.

- Pressure Relief: Some monoflange designs incorporate a pressure relief valve. This safety feature protects the instrument from overpressure situations.

- Flow Control: Certain monoflange valves include an integral needle valve for regulating flow. This allows for fine-tuning the flow rate to the instrument.

- Corrosion Resistance: Monoflanges can be constructed from various corrosion-resistant materials, like stainless steel or exotic alloys. This makes them suitable for harsh chemical environments.