A lined sight glass is a 360 degree viewing device installed in pipelines or vessels, featuring a transparent window typically made of toughened borosilicate glass. It allows operators to visually monitor the flow and condition of process fluids, ensuring safe and efficient operation in industries handling aggressive chemicals.

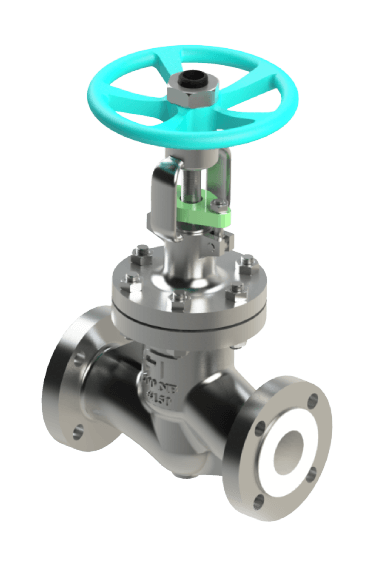

PTFE Lined Sight Glass

PTFE Lined sight glasses are vital components for monitoring industrial processes, offering operators a clear and safe way to observe the flow and condition of Corosive fluids in real-time. Built with a toughened borosilicate glass window, these devices are encased in frames lined with corrosion-resistant Teflon such as PTFE, PFA, FEP, or PVDF. Designed to meet DIN 7080 standards, ideal for industries like chemical processing, pharmaceuticals, water treatment, and food and beverage production, where handling aggressive chemicals and high temperatures is routine.

To withstand challenging operational environments, the manufacturing of lined sight glasses The outer frame is often made from ductile iron, cast steel or stainless steel , providing structural integrity. The inner Teflon lining, with a thickness ranging from 3 mm to 5 mm, offers exceptional chemical resistance. The toughened borosilicate glass tube, known for its high thermal resistance and clarity, allows for 360-degree viewing of the process flow. To prevent leaks, precise engineering ensures a tight seal between the glass and the lined flanges, often achieved through the use of gaskets or seals compatible with a wide range of chemicals.

Incorporating lined sight glasses into your processes boosts operational safety, efficiency, and sustainability. The clear visibility allows for instant detection of flow irregularities, enabling quick corrections to prevent costly system failures. Corrosion-resistant linings extend their lifespan, cutting down on maintenance costs and reducing downtime. For industries like pharmaceuticals and food processing, their hygienic design ensures safe operations without exposing processes to external contamination. By delivering reliable, leak-free performance, these sight glasses help minimize waste, optimize resource use, and support sustainable industrial practices.

Specifications | Features |

|---|---|

Types: Tubular, Double Window Sight glass & flow Indicator Design Standard: DIN 7080, ISO 3585 Construction Material: Ductile Iron, Cast Steel, Stainless Steel Size Range: 15 mm to 200 mm Temperature Range: -30°C to +230°C Pressure Rating: PN 6 to 15 End Connections: Flanged (ANSI B16.5 / B16.42) Spark Test: 15 K.V.D.C Conductivity: 0.20 to 0.6 W/mK Lining Material: PTFE (ASTM D4895), PFA (ASTM D 3307), FEP (ASTM D 2116), PVDF (ASTM D 3322), PP (ASTM D 4101) Lining Thickness: 3 mm to 5 mm Coefficient Of Friction : 0.05 to 0.10 Hydraulic Test: 10 Kg/cm² |

|

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is a lined sight glass, and why is it used in industrial applications?

- What materials are commonly used for the lining in sight glasses?

High Quality Teflon lining materials include PTFE (ASTM D4895), PFA (ASTM D 3307), FEP (ASTM D 2116), PVDF (ASTM D 3322), PP (ASTM D 4101). These materials offer excellent chemical resistance, making them suitable for corrosive environments.

- How does the choice of lining material affect the performance of a sight glass?

The lining material determines the sight glass's compatibility with various chemicals, its temperature and pressure ratings, and its overall durability. Selecting the appropriate lining from PFA (Perfluoroalkoxy), FEP (Fluorinated Ethylene Propylene), and PVDF (Polyvinylidene Fluoride), ensures optimal performance and longevity in specific process conditions.

- What maintenance practices are recommended for lined sight glasses?

Its SS tie rod cage design helps remove glass without disturbing the whole structure. Yet Regular inspections for signs of wear, corrosion, or damage are essential.

- What standards and certifications should lined sight glasses comply with?

Compliance with standards such as DIN 7080 and ISO 3585 is common. Additionally, adherence to industry-specific certifications ensures suitability for particular applications.

- How do lined sight glasses contribute to process safety?

They provide real-time visual monitoring of process fluids, enabling early detection of anomalies like contamination or flow issues, which is crucial for maintaining process integrity and safety.

- In which industries are Ptfe sight glasses most beneficial?

Lined sight glasses are particularly advantageous in industries such as chemical processing, pharmaceuticals, water treatment, and food and beverage production. Their corrosion-resistant linings and clear visibility make them ideal for monitoring processes involving aggressive or hazardous fluids.

- How do Tubular sight glasses enhance safety in industrial processes?

By providing real-time visual monitoring of process fluids, lined sight glasses enable operators to detect anomalies such as contamination, flow irregularities, or equipment malfunctions promptly. This immediate detection allows for swift corrective actions, reducing the risk of accidents, spills, or system failures, thereby enhancing overall process safety.

- In what ways do Ptfe Lined sight glasses contribute to sustainability?

Lined sight glasses contribute to sustainability by minimizing the risk of leaks and spills, which can lead to environmental contamination. Their durable construction reduces the need for frequent replacements, decreasing material consumption and waste. Additionally, by ensuring process integrity, they help maintain efficient operations, conserving energy and resources.

Industries where PTFE Lined Sight Glass Valve is Used

Chemical Processing Industry

Pharmaceutical Industry

Water Treatment Industry

Food and Beverage Industry

Oil and Gas Industry

Applications

- Monitoring Corrosive Reactions: Lined sight glasses allow operators to observe reactions involving aggressive chemicals, ensuring they proceed as intended.

- Flow Verification: They enable real-time monitoring of chemical flow rates, assisting in maintaining optimal process conditions.

- Contamination Detection: Operators can visually inspect for impurities or foreign particles in chemical streams, facilitating prompt corrective actions.

- Pressure Assessment: By observing fluid behavior, sight glasses help assess pressure conditions within reactors and pipelines.

- Batch Consistency Checks: They assist in verifying the consistency of chemical batches, ensuring product quality.

- Sterility Assurance: They help confirm that sterilization processes are effective by allowing visual inspection of sterilized media.

- Contamination Detection: Visual checks can identify potential contamination in pharmaceutical formulations.

- Leak Detection: They assist in identifying leaks in pipelines and tanks, preventing water loss and contamination.

- Changeover Confirmation: Operators can confirm that product changeovers have been completed successfully by visually inspecting the system.