A T‑type lined Basket Strainer is an inline filtration device that uses a basket-like filtering element often “lined” with a protective polymer like PTFE or pfa. The “T‑type” designation refers to its T‑shaped body.

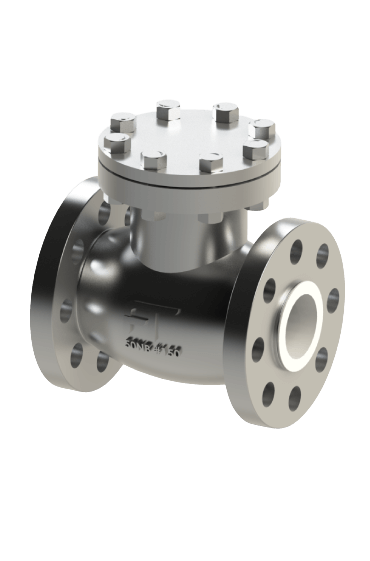

PTFE Lined Basket Strainer

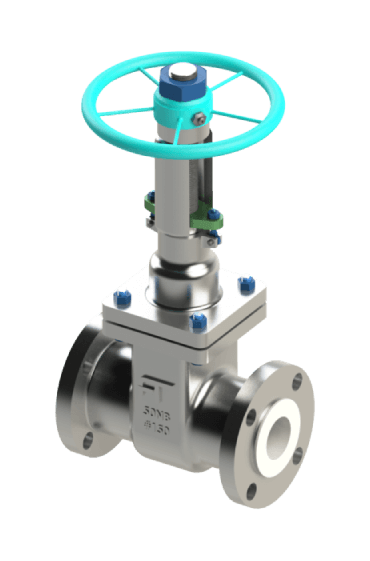

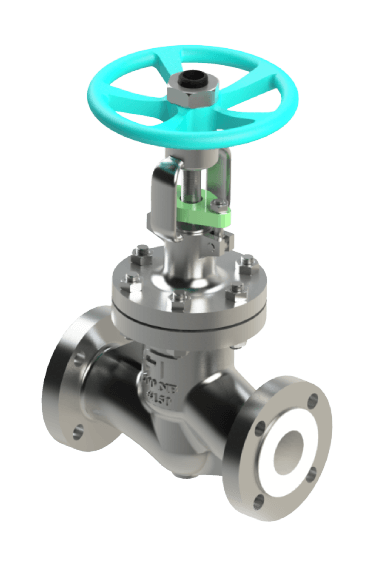

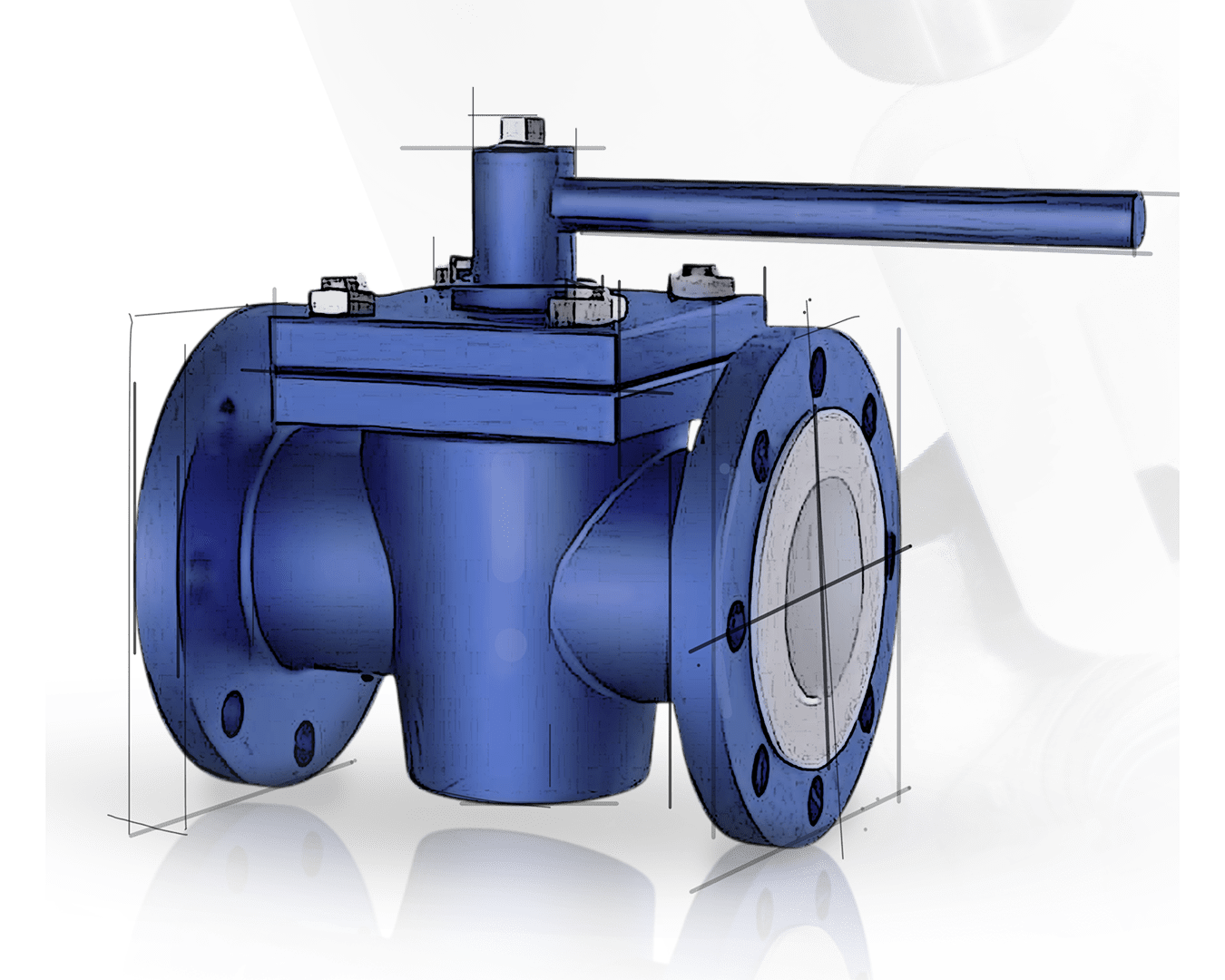

A PTFE Lined Basket Strainer is a filtration device designed to remove debris and contaminants from process fluids in industrial pipelines. T-shaped configuration with PTFE Basket facilitates smooth flow while capturing unwanted particles. The interior surfaces of this T - type strainer are lined with 3 to 5 mm thick high-performance fluoropolymers like PTFE / FEP / PFA to enhance the strainer’s ability to withstand extreme conditions while offering superior protection to pipeline systems.

This PTFE lined Strainer comes with a mesh Basket, As fluid passes through this Ø1mm Perforated PTFE Basket, 40 mesh, 60 mesh solid particles are trapped within the Filter basket, allowing clean fluid to proceed downstream. High Quality Teflon lining ensures to handle a wide range of corrosive or abrasive substances without degradation. Regular maintenance involves removing the Easy basket for cleaning, this process becomes more efficient with quick top opening and Ptfe Drain plug.

By effectively removing contaminants, these PTFE lined T - Type basket strainer support sustainability efforts by minimizing waste and preventing environmental contamination.Its T-shaped configuration allows for efficient integration into piping systems, facilitating the smooth flow of liquids or gases while capturing unwanted particles. Furthermore, the ability to handle high flow capacities and the option to select different mesh sizes enable these strainers to be tailored to specific filtration requirements, ensuring optimal performance across diverse applications.

Specifications | Features |

|---|---|

Design Standards: ASME B16.5, DIN EN 1092 / ASTM A105 / IS 2062 Size Range: 15 mm to 300 mm & more on request Type: Eccentric, Concentric Y Type Strainer End Connections: ANSI B16.5 Material: Ductile Iron GGG40.3 / ASTM A395, Cast Steel ASTM A216 Gr. WCB, ASTM A312 TP 304 / 316: SCH.-40 Flange Material: ASTM A 105 (N) / IS 2062 / ASTM A351 Gr. CF8 & CF8M Flange Dimensions: DIN PN10/16, BS 10, ASME 150 / 300 Lining Material: PFA (ASTM D3307), FEP (ASTM D2116), PVDF (ASTM D3322), PP (ASTM D4101), HDPE, PTFE (ASTM D4895) Lining Options: PVDF, ETFE, PP, HDPE Lining Thickness: Minimum 3.5 mm / 6.0 mm overall Lining Spark Test: 20 KVDC After lining Hydraulic Test: 29 Kg/Cm² After lining Mesh Size: 40 to 60 Mesh Hydraulic Test: 20 Kg/cm² Spark Test: 15 K.V.D.C |

|

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is a T Type lined Basket Strainer?

- What is the purpose of the lining in T type Strainer?

The lining (for example, a PTFE or Teflon layer) provides enhanced chemical resistance and prevents corrosive fluids from attacking the metal substrate. It also helps to improve cleaning efficiency and prolongs the service life of the strainer in aggressive environments.

- Which materials are commonly used for the lining and basket?

Lining materials typically include PTFE, Viton, or other specialized polymers chosen for their chemical inertness and temperature tolerance.

- What applications are best suited for a lined Basket Strainer T‑type?

They are widely used in applications where the process fluid is aggressive or laden with particulates—for example, in chemical processing, oil and gas systems, water treatment, and even in some high‐temperature steam applications.

- How is the correct mesh size and lining specification determined?

These Basket Strainer comes with 40 and 60 basket mesh configuration selecting the right one depends on customers usage and possible thickness of debris.

- How is a lined Basket Strainer T‑type installed?

These strainers are generally installed in horizontal pipelines at accessible locations. Installation includes aligning the strainer (with its T‑shaped body) in the correct orientation so that the debris collection chamber is at the top.

- What routine maintenance is recommended?

The strainer's design allows for easy removal and cleaning of the filter basket without disassembling the entire unit,& smooth PTFE lining resists buildup, reducing cleaning frequency and extending maintenance intervals.

- How Often Should the Strainer Be Cleaned?

The cleaning frequency depends on the concentration of contaminants and the fluid characteristics. In the heavy-duty industry on a weekly basis. In less contaminated systems, monthly cleaning might suffice.

- What troubleshooting steps should be taken if the strainer shows issues?

Common problems include an unexpected increase in pressure drop or visible signs of wear on the lining. Troubleshooting should begin with checking for clogging in the basket and ensuring the drain valve is functioning properly.

Industries where PTFE Lined Basket Strainer Valve is Used

Chemical Industry

Pharmaceutical Industry

Petrochemical Industry

Water Treatment Industry

Food & Beverage Industry

Application

- Removal of solid impurities from corrosive chemicals and acids.

- Ensuring clean input in reactor feed lines.

- Protecting filling machines and piping systems.

- Filtration of solvents used in API manufacturing.

- Filtration in LPG and natural gas production lines.